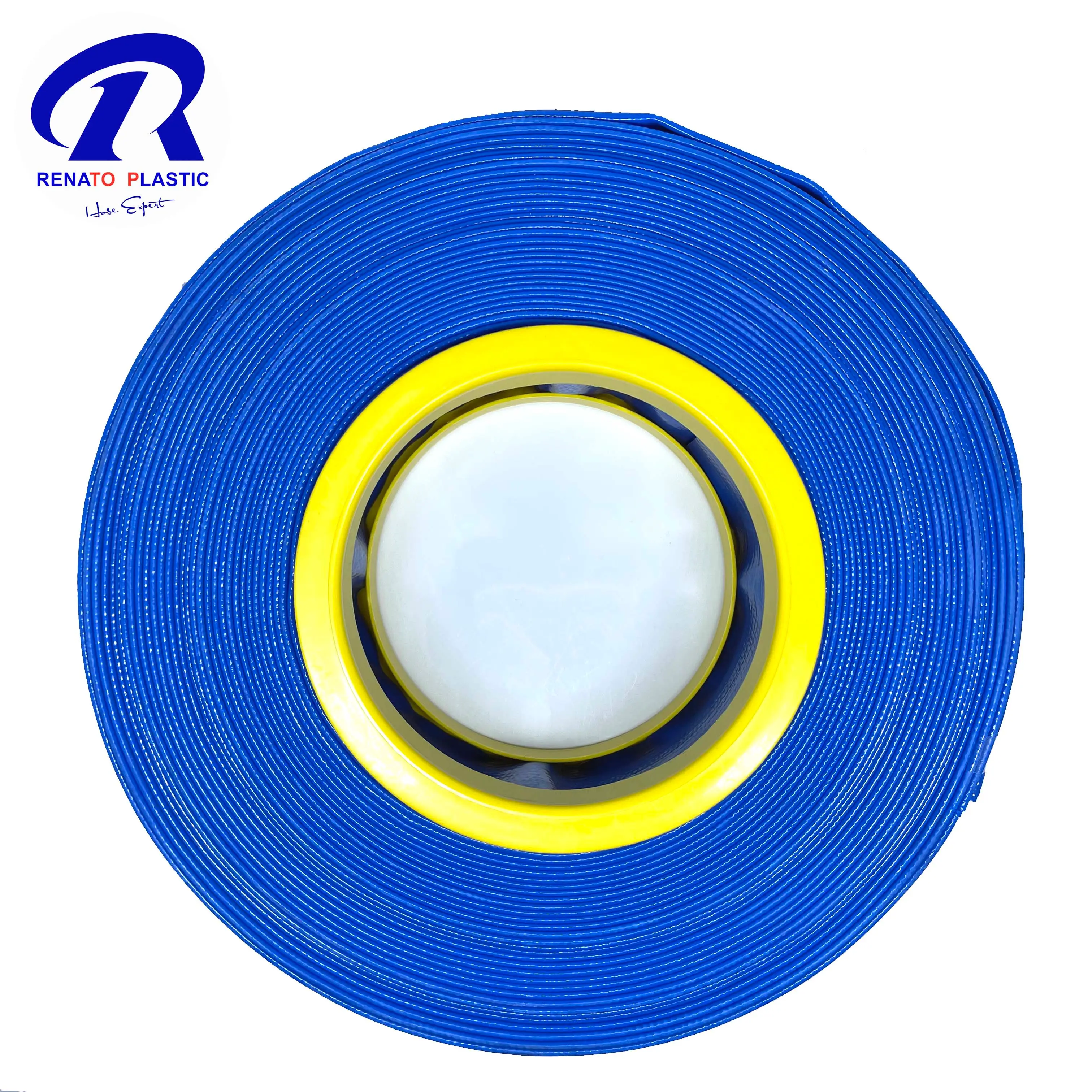

What is 4 Inch Lay Flat Discharge Hose?

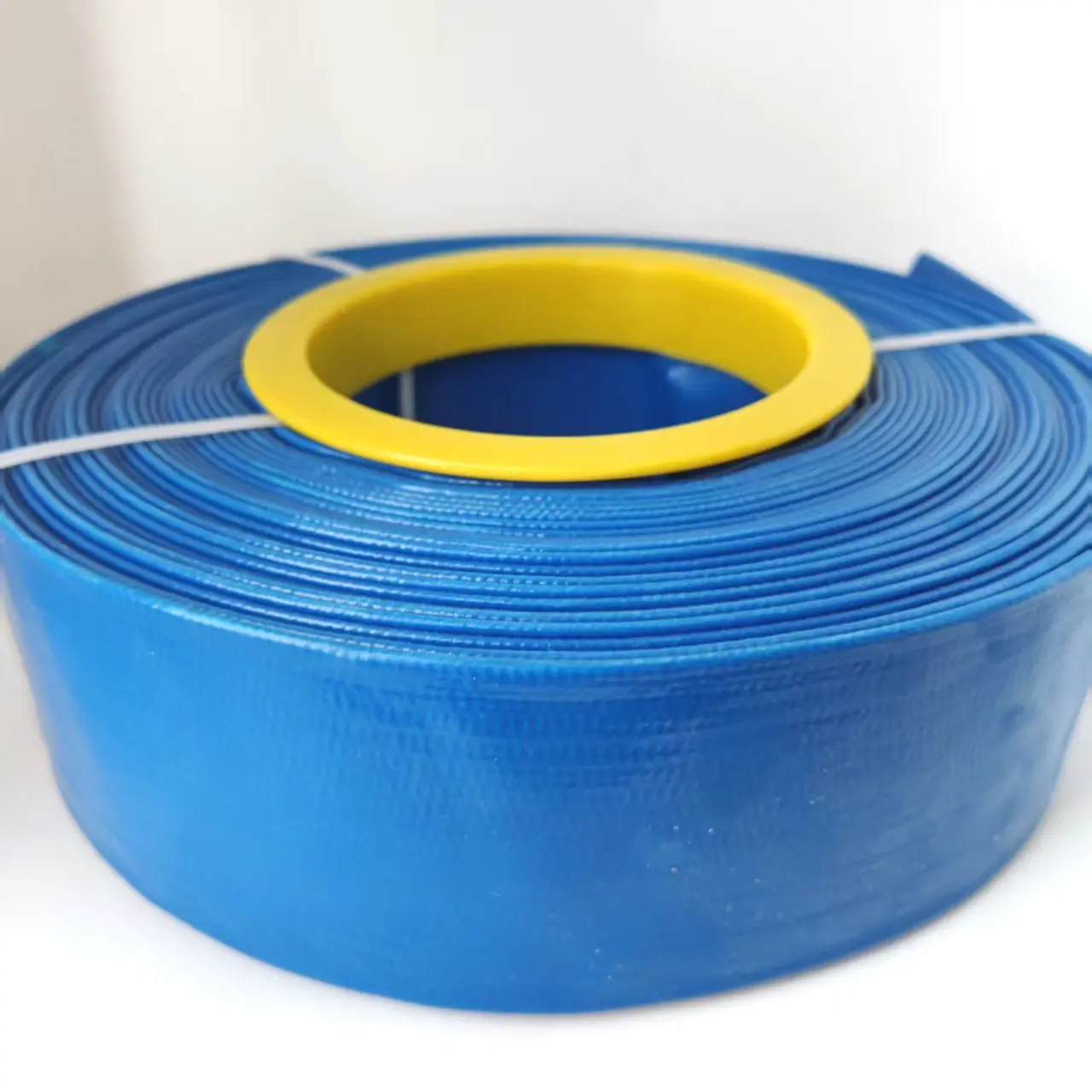

The 4 Inch Lay Flat Discharge Hose is an essential tool for a variety of industries, particularly in agriculture, construction, and industrial fluid transfer. Designed for flexibility, durability, and ease of use, this hose is perfect for applications that involve transporting water, slurries, or other liquids over long distances.

This product is made from high-quality PVC (Polyvinyl Chloride) or TPU (Thermoplastic Polyurethane), reinforced with polyester fibers to ensure strength and resistance to high pressures. The lay-flat design allows the hose to collapse when not in use, making it highly portable and easy to store.

Features of the 4 Inch Lay Flat Discharge Hose

Flexible and Lightweight:

The hose is incredibly flexible, allowing for easy handling, even in tight spaces. Despite its strength, it is lightweight, which makes it easy to deploy, roll up, and transport.

Durable Construction:

Made from reinforced PVC or TPU material, this hose is built to withstand harsh environments, including exposure to chemicals, abrasion, and extreme weather conditions.

High-Pressure Capacity:

The hose is designed to handle high-pressure water discharge, with a working pressure range of 4 to 6 Bar and a burst pressure capacity of 12 to 18 Bar. This makes it suitable for heavy-duty applications such as dewatering, irrigation, and industrial liquid transfer.

UV and Weather Resistant:

With built-in UV resistance, the hose is ideal for outdoor use. It can handle prolonged exposure to sunlight without degrading, making it perfect for agriculture and construction environments.

Temperature Range:

It operates efficiently in a wide temperature range of -10°C to +60°C, ensuring performance in both hot and cold conditions.

Versatile Applications:

The hose is widely used in agriculture for irrigation systems, in construction for site dewatering, and in industrial settings for liquid transfer processes. Its robust design allows for use in rugged terrains and demanding conditions.

Technical Specifications Table

| Specification | Details |

|---|---|

| Diameter | 4 Inches (100 mm) |

| Material | Reinforced PVC or TPU |

| Working Pressure | 4 to 6 Bar |

| Burst Pressure | 12 to 18 Bar |

| Length Options | 10 meters, 20 meters, 30 meters, 50 meters |

| Weight | Varies based on length (2-3 kg per meter) |

| Reinforcement | High-tensile polyester fibers |

| Temperature Range | -10°C to +60°C |

| UV Resistance | Yes |

| Fitting Options | Standard or custom couplings available |

Price Range

The cost of a 4-inch lay flat discharge hose depends on factors such as length, material, and fittings. Below is an estimated price range:

| Length | Factory Price | Brand Price | Retail Price |

|---|---|---|---|

| 10 meters | $35 - $50 | $55 - $70 | $75 - $90 |

| 20 meters | $60 - $80 | $85 - $100 | $110 - $130 |

| 30 meters | $90 - $120 | $130 - $150 | $160 - $180 |

| 50 meters | $150 - $200 | $200 - $250 | $250 - $300 |

Applications of the 4 Inch Lay Flat Discharge Hose

Agricultural Irrigation:

The 4-inch lay flat discharge hose is frequently used for large-scale irrigation systems to transport water from pumps to fields. Its high flow rate and flexibility make it ideal for farming needs.

Construction Site Dewatering:

On construction sites, the hose is essential for draining excess water from pits, trenches, and low-lying areas. Its ability to handle high water pressure ensures efficient water removal.

Industrial Fluid Transfer:

In industrial processes, this hose is utilized to transport chemicals, wastewater, and other fluids across facilities. Its chemical-resistant properties make it a reliable choice for harsh environments.

Emergency Flood Response:

The lay flat design makes this hose a great tool for emergency floodwater pumping. It can be easily stored and quickly deployed when needed.

Lifespan and Maintenance

With proper care and usage, the 4 Inch Lay Flat Discharge Hose can last 5 to 10 years. The lifespan largely depends on how frequently it’s used and the conditions it is exposed to.

Maintenance Tips:

Always drain the hose after use to prevent water stagnation, which can lead to internal damage.

Store the hose in a cool, dry place, away from direct sunlight when not in use.

Regularly inspect for wear and tear, especially around the fittings.

Avoid dragging the hose over sharp objects to prevent cuts or abrasions.

The 4 Inch Lay Flat Discharge Hose is a versatile, durable, and cost-effective solution for a variety of water discharge applications. Its lightweight and flexible design makes it easy to handle, while its reinforced construction ensures that it can withstand demanding environments. Whether you're irrigating fields, draining construction sites, or transferring industrial fluids, this hose offers reliable performance. With a long lifespan and robust resistance to UV, weather, and chemicals, it's a valuable investment for both professionals and hobbyists alike.

For more information or to place a bulk order, contact your nearest supplier to get the best pricing and custom options tailored to your needs.

PVC lay flat discharge hoses specifications

PVC lay flat discharge hoses come in various specifications to suit different applications and requirements. The key specifications include diameter, length, working pressure, and burst pressure. Here are some common specifications:

Diameters

PVC lay flat discharge hoses are available in a range of diameters. Common sizes include:

1 inch (25 mm)

1.5 inch (38 mm)

2 inch (51 mm)

2.5 inch (63 mm)

3 inch (76 mm)

4 inch (102 mm)

6 inch (152 mm)

8 inch (203 mm)

Lengths

The length of PVC lay flat hoses can vary depending on the application. Typical lengths include:

25 feet (7.6 meters)

50 feet (15.2 meters)

100 feet (30.5 meters)

Custom lengths are also available based on specific needs.

Working Pressure

The working pressure of PVC lay flat discharge hoses varies depending on the construction and intended use. Common working pressures include:

45 PSI (3.1 bar)

80 PSI (5.5 bar)

100 PSI (6.9 bar)

150 PSI (10.3 bar)

Burst Pressure

Burst pressure is typically higher than the working pressure, providing a safety margin. Common burst pressures include:

150 PSI (10.3 bar)

200 PSI (13.8 bar)

300 PSI (20.7 bar)

Temperature Range

PVC lay flat hoses are designed to perform across a range of temperatures. Common temperature ranges include:

-10°C to 60°C (14°F to 140°F)

-20°C to 80°C (-4°F to 176°F)

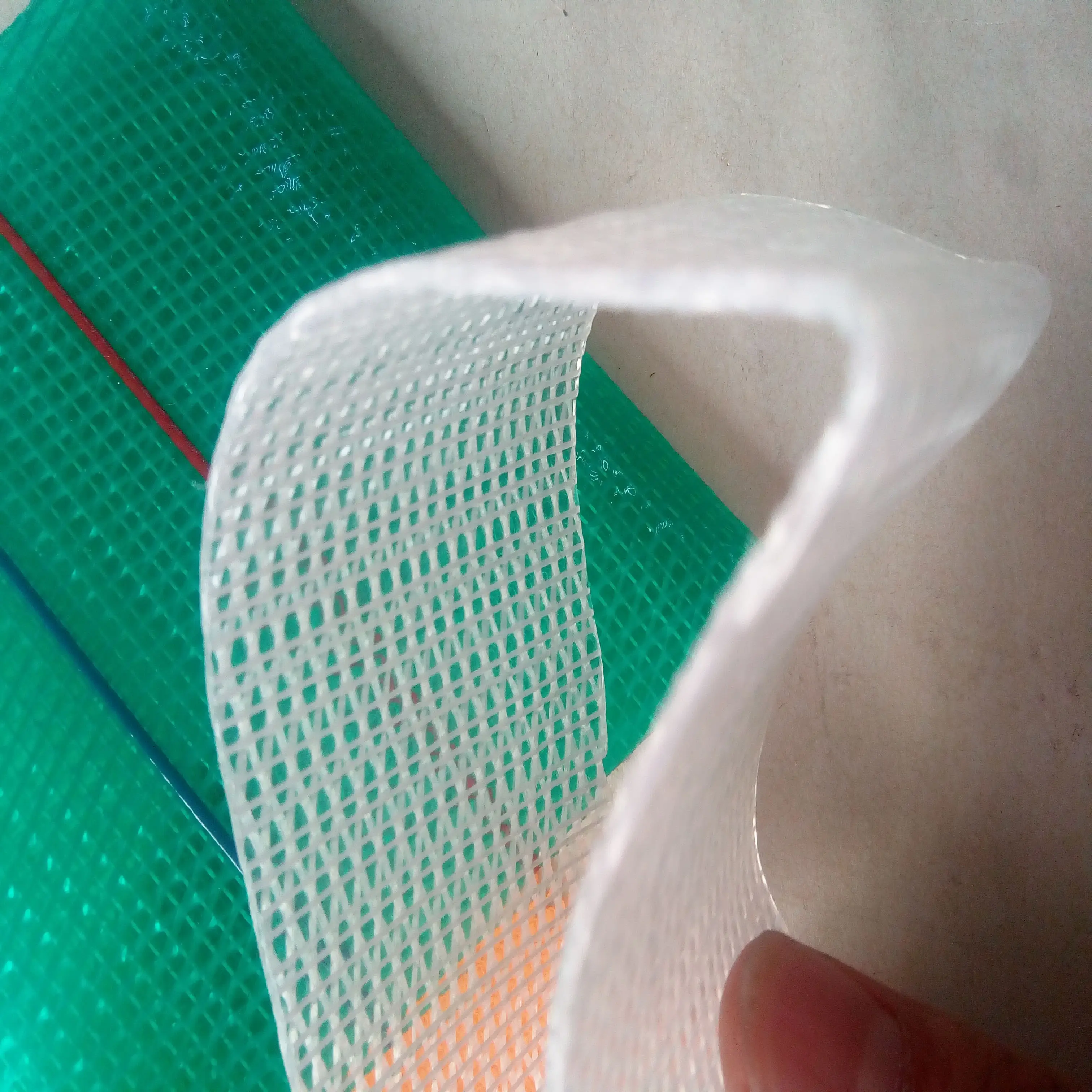

Material and Construction

PVC lay flat hoses are typically made from polyvinyl chloride (PVC) with polyester reinforcement. This construction provides durability, flexibility, and resistance to chemicals, abrasion, and UV radiation.

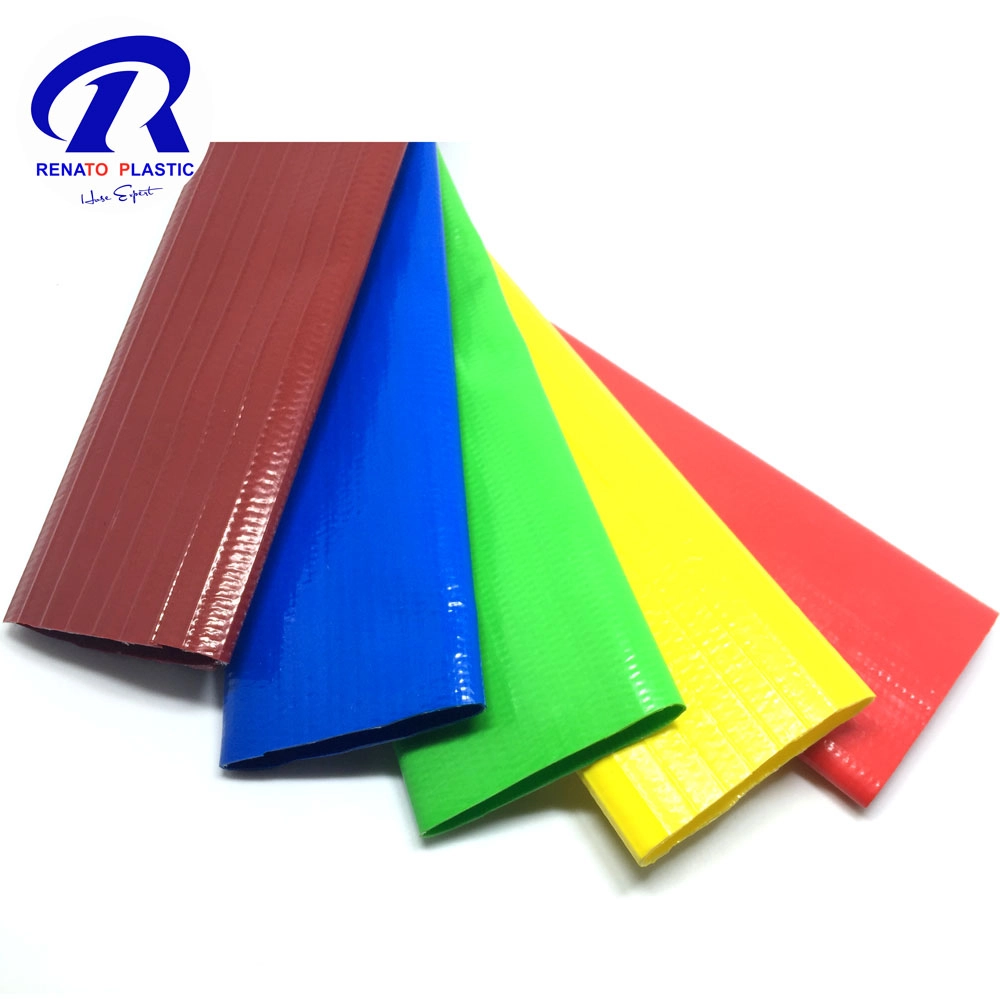

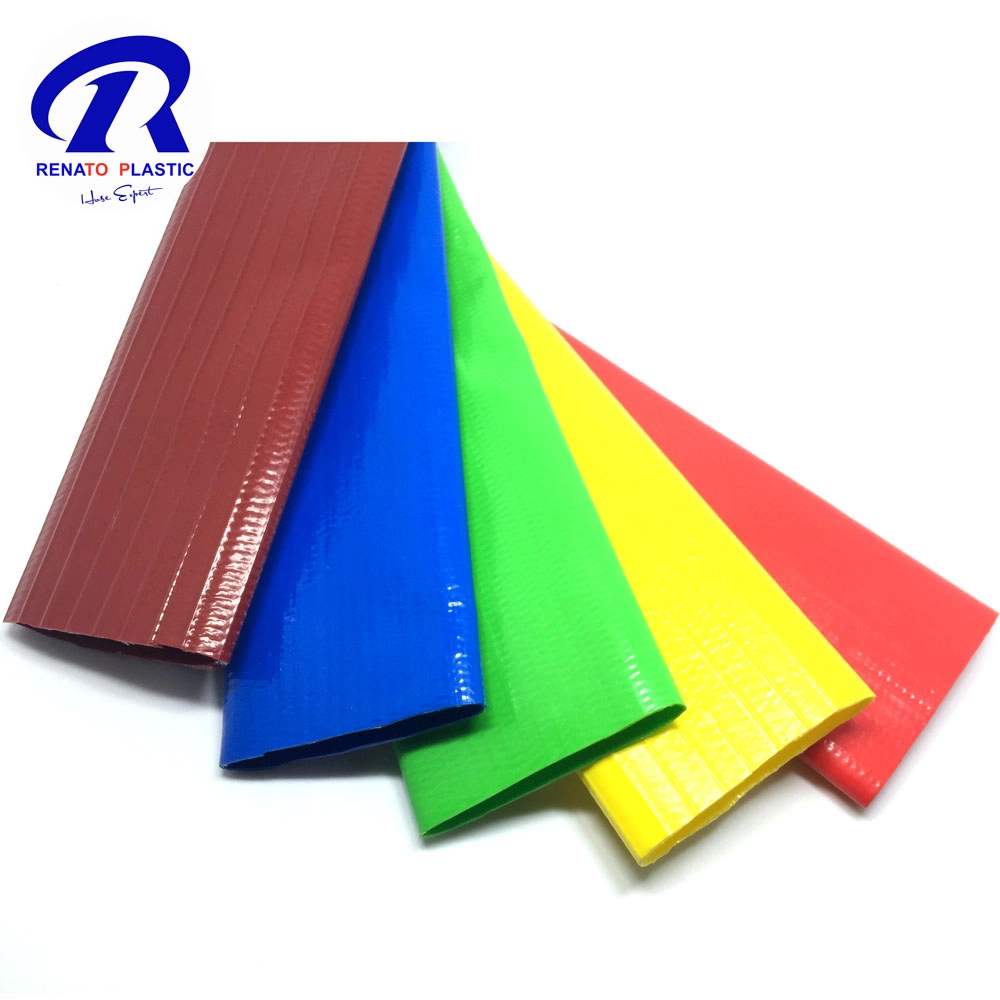

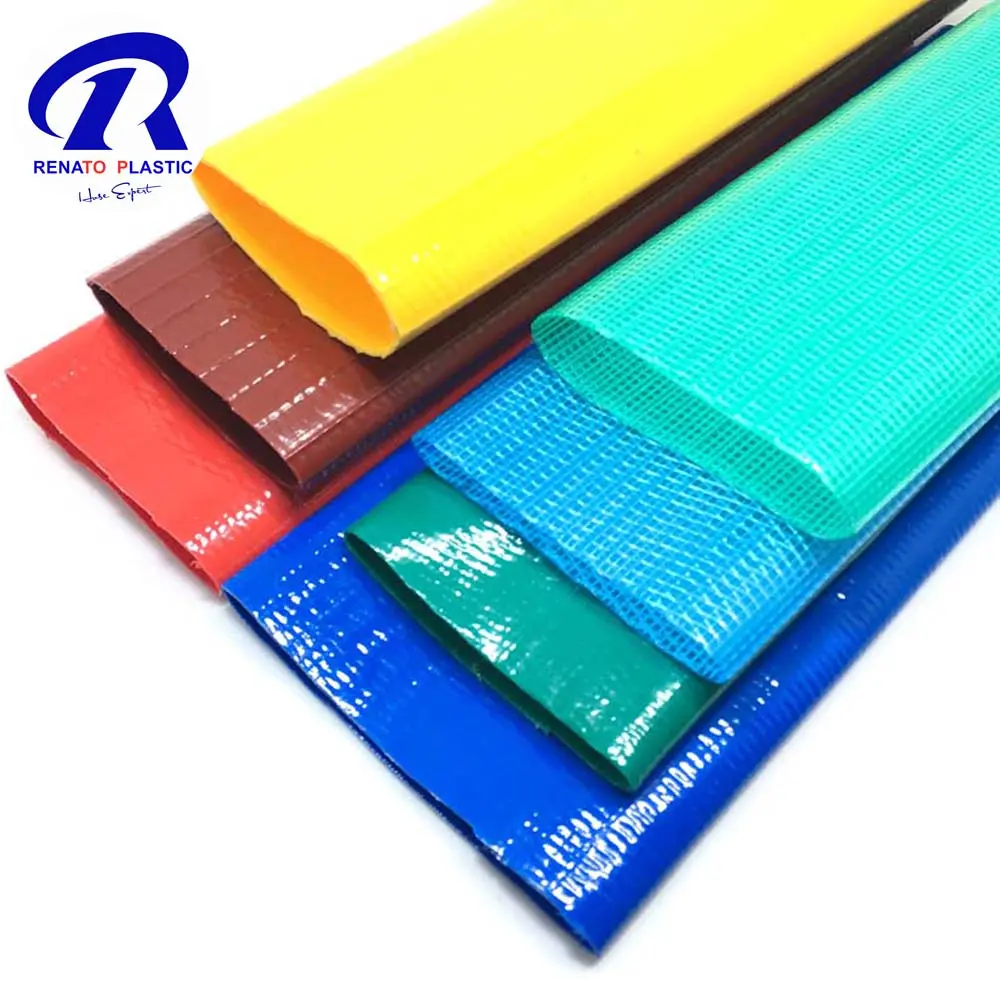

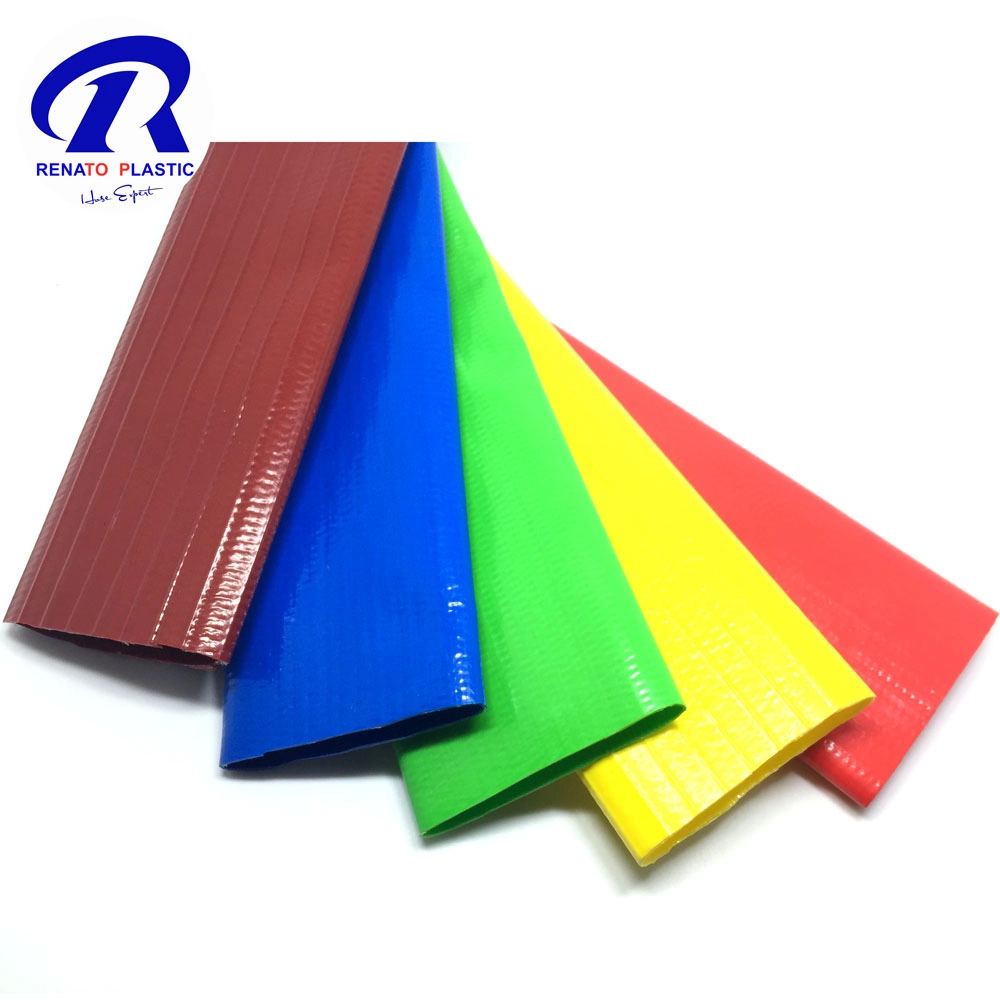

Colors

PVC lay flat discharge hoses are available in various colors for different applications and preferences. Common colors include:

Blue

Red

Yellow

Green

Black

Applications

Depending on the specifications, PVC lay flat discharge hoses can be used in various applications such as:

Agricultural irrigation

Construction dewatering

Industrial fluid transfer

Municipal water supply

Emergency and disaster response

These specifications allow for a wide range of options to meet specific needs in different industries and applications.

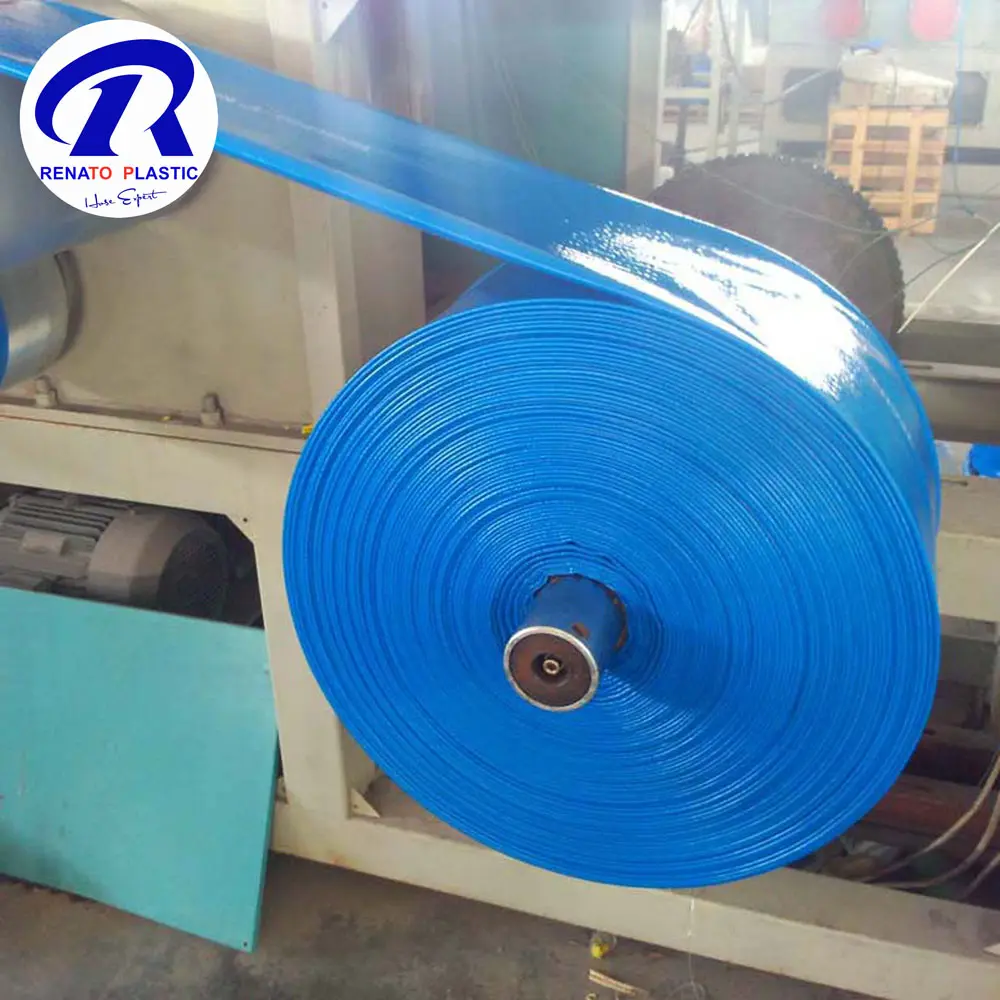

How to make PVC lay flat discharge hose?

Making a PVC lay flat discharge hose involves several steps, including material selection, extrusion, reinforcement, curing, and quality control. Here is a detailed overview of the process:

1. Material Selection

The primary materials used are:

Polyvinyl Chloride (PVC) Resin: The main material for the hose.

Plasticizers: To make the PVC flexible.

Stabilizers: To enhance the durability and heat resistance of the hose.

Colorants: To add the desired color to the hose.

Polyester Yarn: For reinforcement, providing strength and flexibility.

2. Extrusion of the Inner Layer

The process begins with the extrusion of the inner PVC layer:

Mixing: PVC resin, plasticizers, stabilizers, and colorants are mixed to create a homogenous compound.

Extrusion: The mixed compound is fed into an extruder, which heats and shapes the PVC into a tube. This forms the inner layer of the hose.

3. Reinforcement

The next step is to reinforce the PVC tube with polyester yarn:

Braiding or Knitting: The extruded PVC tube is passed through a braiding or knitting machine that wraps polyester yarn around the tube. This reinforcement provides additional strength and prevents the hose from bursting under pressure.

4. Extrusion of the Outer Layer

After reinforcement, the outer layer of PVC is applied:

Second Extrusion: The reinforced tube is fed through another extruder that applies an outer layer of PVC, encapsulating the polyester yarn. This outer layer protects the reinforcement and provides durability.

5. Curing

The extruded and reinforced hose needs to be cured to ensure the PVC layers bond properly:

Heating: The hose is passed through an oven or curing chamber where it is heated to a specific temperature. This process ensures that the inner and outer PVC layers fuse together with the reinforcement, creating a strong, cohesive hose structure.

6. Cooling

After curing, the hose is cooled to solidify the PVC and stabilize its shape:

Water Bath: The hose is typically passed through a water bath to cool it rapidly and set its dimensions.

7. Quality Control

The final step is to inspect and test the hose to ensure it meets quality standards:

Visual Inspection: The hose is checked for any surface defects, inconsistencies, or irregularities.

Pressure Testing: The hose is subjected to pressure tests to verify it can withstand the specified working and burst pressures.

Dimensional Checks: The hose’s diameter, thickness, and length are measured to ensure they meet the required specifications.

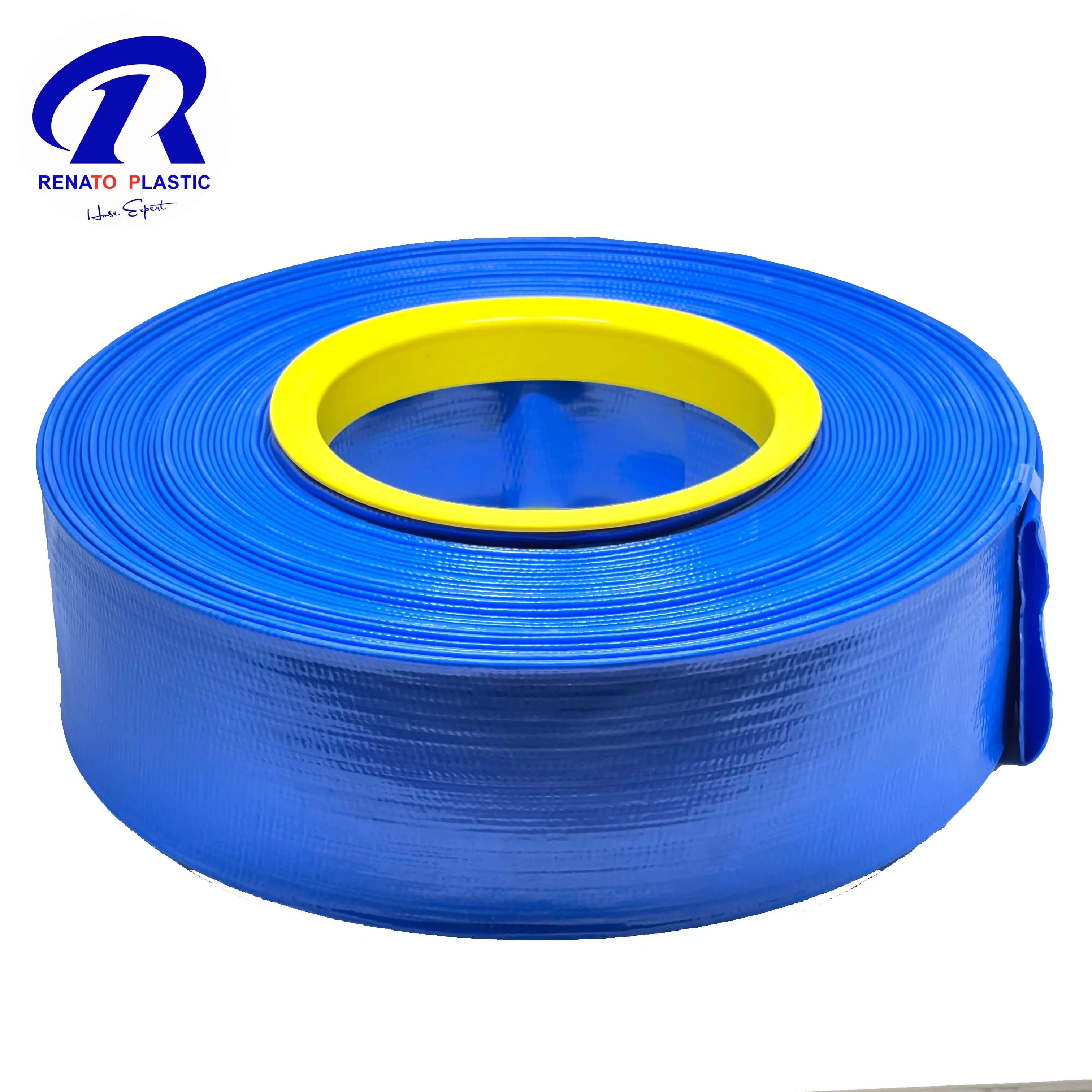

8. Cutting and Packaging

Once the hose passes quality control, it is cut to the desired lengths and prepared for packaging:

Cutting: The hose is cut into standard or custom lengths as required by the customers.

Fittings: Quick-connect fittings or camlock couplings may be attached if specified.

Packaging: The hose is coiled, strapped, and packaged for shipment.

Summary

The manufacturing process of PVC lay flat discharge hoses involves a series of steps to ensure the hose is durable, flexible, and capable of handling various pressures and conditions. By selecting high-quality materials and adhering to strict manufacturing standards, manufacturers produce hoses that meet the diverse needs of agricultural, construction, industrial, and emergency applications.