Flexible PVC hose is one of those products that quietly holds modern industry together. You’ll find it everywhere—agriculture, construction, manufacturing, mining, food processing, home gardens, and even medical equipment. It’s lightweight, adaptable, affordable, and surprisingly versatile.

Yet many buyers only know it by appearance, not by performance. They choose based on price alone and later discover issues with pressure, kinking, chemical resistance, or lifespan.

This article explains what flexible PVC hose really is, how it’s made, what types exist, where it performs best (and where it doesn’t), and how to choose the right one for your application. Practical knowledge first. Buzzwords last.

What Is Flexible PVC Hose?

A flexible PVC hose is a hose made primarily from polyvinyl chloride (PVC) combined with plasticizers and additives that give it flexibility, durability, and resistance to environmental factors.

Unlike rigid PVC pipes, flexible PVC hoses can bend, coil, stretch slightly, and absorb vibration—making them ideal for fluid transfer where movement, portability, or irregular routing is required.

At its core, a flexible PVC hose is designed to:

Transport liquids, air, or light solids

Withstand internal pressure or vacuum

Remain flexible across a working temperature range

Why PVC? The Material Science in Simple Terms

PVC is popular because it sits at a rare intersection of properties:

Naturally corrosion resistant

Chemically stable

Easy to process

Cost-effective at scale

On its own, PVC is rigid. To make it flexible, manufacturers add plasticizers, which loosen the polymer chains and allow the material to bend without cracking.

Additives may also include:

UV stabilizers

Anti-aging agents

Reinforcement fibers

Flame retardants

Food-grade or medical-grade compounds

The exact formula determines performance.

How Flexible PVC Hose Is Manufactured

Understanding the manufacturing process helps explain why hoses differ so much in quality.

Step 1: Raw Material Compounding

PVC resin is blended with plasticizers, stabilizers, and functional additives. Quality hoses use virgin PVC; lower-grade products may include recycled material.

Step 2: Extrusion

The compound is heated and pushed through a die to form the hose shape. For reinforced hoses, this step is combined with reinforcement insertion.

Step 3: Reinforcement (Optional)

Depending on the design, manufacturers may add:

Polyester yarn braiding

Steel wire spirals

PVC rigid helix

Reinforcement dramatically affects pressure rating and vacuum resistance.

Step 4: Cooling and Sizing

The hose is cooled, calibrated for diameter accuracy, and cut to length.

Step 5: Quality Testing

Reputable manufacturers test:

Working pressure

Burst pressure

Flexibility at low temperatures

Aging and UV resistance

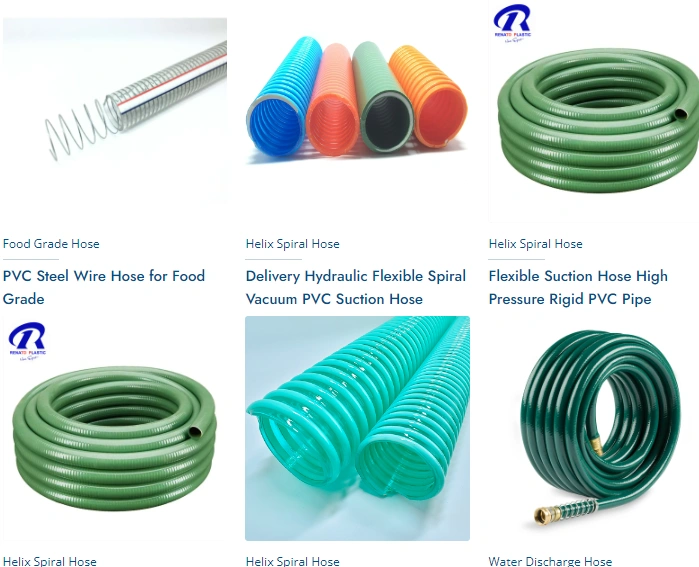

Main Types of Flexible PVC Hose

Flexible PVC hose is not a single product. It’s a family of designs optimized for different jobs.

Clear PVC Hose

Transparent, lightweight, and flexible.

Best for:

Water transfer

Chemical observation

Laboratory use

Low-pressure applications

Advantages:

Visual flow monitoring

Easy leak detection

Limitations:

Lower pressure rating

UV sensitivity without additives

PVC Fiber Reinforced Hose

Reinforced with polyester yarn between PVC layers.

Best for:

Water supply

Air compressors

Irrigation

Light industrial use

Advantages:

Higher pressure resistance

Maintains flexibility

This is one of the most widely used PVC hose types globally.

PVC Steel Wire Reinforced Hose

Contains a steel wire helix embedded in the wall.

Best for:

Suction and discharge

Vacuum applications

Slurry transfer

Advantages:

Anti-collapse under vacuum

Strong structural integrity

PVC Lay Flat Hose

Designed to flatten when empty.

Best for:

Water discharge

Irrigation

Flood control

Construction sites

Advantages:

Easy storage

Lightweight

Large diameter options

PVC Spiral Suction Hose

Rigid PVC helix with flexible wall.

Best for:

Sand

Mud

Agricultural suction

Industrial waste

Advantages:

Abrasion resistance

Shape retention

Factory price

Factors influencing price include:

Whether virgin PVC raw materials are used

Plasticizer and stabilizer grades

Wall thickness and reinforcing layer structure

Order quantity (MOQ)

Whether food-grade/industrial-grade certification is required. The following are common reference prices for exports from Chinese factories, excluding freight, customs duties, and special certification fees. Actual prices are significantly affected by raw materials, specifications, and quantity.

| Hose Type | Inner Diameter | Length | Working Pressure | Reference Price (USD) |

|---|---|---|---|---|

| Clear PVC Hose | 6–25 mm | 30–100 m | 4–8 bar | $0.20 – $0.80 / m |

| PVC Fiber Reinforced Hose | 8–50 mm | 30–100 m | 8–20 bar | $0.50 – $1.80 / m |

| PVC Steel Wire Reinforced Hose | 19–100 mm | 30–50 m | 6–15 bar | $1.50 – $6.50 / m |

| PVC Lay Flat Hose | 1″–8″ | 50–100 m | 4–10 bar | $0.40 – $2.20 / m |

| PVC Spiral Suction Hose | 25–150 mm | 30 m | Vacuum / Low pressure | $1.80 – $7.50 / m |

Key Performance Characteristics Explained

Flexibility

Flexibility depends on plasticizer content and wall thickness. More flexibility usually means lower pressure resistance.

Pressure Rating

Working pressure: safe continuous use

Burst pressure: failure point (usually 3–4× working pressure)

Never size a hose close to burst pressure.

Temperature Range

Typical flexible PVC hose range:

-10°C to +60°C (14°F to 140°F)

Cold temperatures reduce flexibility. High temperatures accelerate aging.

Chemical Resistance

PVC resists:

Water

Many acids and alkalis

Alcohols

PVC does not perform well with:

Aromatic solvents

Strong oils (unless specially formulated)

Always check chemical compatibility charts.

Advantages of Flexible PVC Hose

Flexible PVC hose remains dominant for good reasons:

Lightweight and easy to handle

Excellent corrosion resistance

Lower cost than rubber hoses

Wide range of sizes and types

Customizable for specific markets

From an economic standpoint, PVC offers one of the best performance-to-cost ratios available.

Limitations You Should Understand

No material is perfect.

Flexible PVC hose limitations include:

Reduced flexibility in cold weather

Shorter lifespan under UV without protection

Lower heat resistance than rubber

Plasticizer migration over long periods

Understanding these limits prevents misuse.

Common Applications by Industry

Agriculture

Irrigation lines

Fertilizer transfer

Water pumps

PVC is favored due to low cost and easy replacement.

Construction

Dewatering

Concrete washout

Dust suppression

Lay flat and suction hoses dominate here.

Industrial Manufacturing

Air lines

Coolant transfer

Chemical handling (light-duty)

Fiber reinforced hoses are common.

Food and Beverage

Water transport

Liquid food transfer (food-grade PVC only)

Material certification is critical.

Home and Garden

Garden hoses

Pond systems

DIY water lines

Flexibility and affordability matter most.

How to Choose the Right Flexible PVC Hose

Many failures happen at the buying stage. Use this logic instead:

What medium? Water, air, chemical, slurry

Pressure requirement? Working pressure + safety margin

Suction or discharge? Collapse resistance matters

Temperature exposure? Climate and fluid temperature

Movement level? Static or dynamic application

Choosing based on diameter alone is a mistake.

Flexible PVC Hose vs Rubber Hose

PVC hoses:

Lighter

Cheaper

Easier to store

Rubber hoses:

Better heat resistance

Better flexibility in cold

Longer lifespan in harsh environments

PVC wins in cost-sensitive, moderate-duty scenarios.

Quality Differences: What Buyers Often Miss

Two hoses that look identical can perform very differently.

Quality indicators include:

Uniform wall thickness

Smooth inner bore

Clear pressure rating markings

Consistent flexibility

Low-cost hoses often sacrifice material purity.

Maintenance and Storage Tips

Avoid prolonged UV exposure

Do not exceed pressure ratings

Drain after use

Store loosely coiled

Simple habits can double service life.

Environmental and Recycling Considerations

PVC is recyclable, but recycling infrastructure varies by region. Many manufacturers now offer:

Reduced plasticizer content

Eco-friendly stabilizers

Sustainability is improving, slowly.

The Real Reason Flexible PVC Hose Dominates the Market

Flexible PVC hose succeeds not because it’s perfect—but because it’s good enough in more situations than almost any alternative.

It balances:

Cost

Performance

Availability

Customization

That balance explains why it remains a global standard.

Final Summary

Flexible PVC hose is a versatile, cost-effective solution for fluid and air transfer across countless industries. Understanding its material properties, limitations, and variations allows buyers to choose smarter, avoid premature failures, and reduce long-term costs.

When selected correctly, flexible PVC hose is not just a consumable—it’s a reliable working tool that quietly does its job, day after day, without drama.

FAQ: Flexible PVC Hose – Buyer & User Questions

1. What is flexible PVC hose mainly used for?

Flexible PVC hose is commonly used for water transfer, air delivery, irrigation, suction and discharge, chemical handling (light-duty), and industrial fluid transport. Different designs suit different pressure and application needs.

2. Is flexible PVC hose suitable for suction applications?

Yes, but only reinforced types.

For suction or vacuum use, you should choose:

PVC steel wire reinforced hose

PVC spiral suction hose

Standard clear or fiber-reinforced hoses may collapse under vacuum.

3. What is the typical lifespan of a flexible PVC hose?

Under normal conditions:

Indoor or shaded use: 3–5 years

Outdoor use with UV exposure: 2–3 years

Proper storage and avoiding overpressure can significantly extend service life.

4. Can flexible PVC hose handle chemicals?

PVC hoses resist water, mild acids, alkalis, and alcohols, but are not suitable for strong solvents, aromatic hydrocarbons, or high-temperature oils unless specially formulated.

Always request a chemical compatibility chart before purchase.

5. What temperature range can flexible PVC hose handle?

Most standard flexible PVC hoses operate between:

-10°C to +60°C (14°F to 140°F)

Cold temperatures reduce flexibility, while excessive heat accelerates aging.

6. How do I choose the right PVC hose?

You should consider:

Medium type (water, air, chemical, slurry)

Working pressure and safety margin

Suction vs discharge

Temperature conditions

Required flexibility

Choosing only by diameter often leads to failure.

7. Is flexible PVC hose food-safe?

Only food-grade PVC hoses are suitable for food or drinking water. These must comply with standards such as:

FDA

EU food-contact regulations

Never assume standard PVC hose is food-safe.

8. Why do some PVC hoses turn hard or yellow over time?

This is usually caused by:

Plasticizer migration

UV exposure

Poor-quality stabilizers

Higher-quality hoses age more slowly and remain flexible longer.

9. Flexible PVC hose vs rubber hose: which is better?

PVC hoses are:

Lighter

Cheaper

Easier to store

Rubber hoses are:

Better for high temperature

More flexible in cold climates

Longer-lasting in harsh environments

PVC is ideal for cost-sensitive, moderate-duty applications.

10. Can flexible PVC hose be customized?

Yes. Manufacturers commonly offer customization for:

Diameter and length

Color and transparency

Pressure rating

Branding and packaging

Special formulations (UV-resistant, anti-static, food-grade)