What is 9/32 Twin Clear Hose?

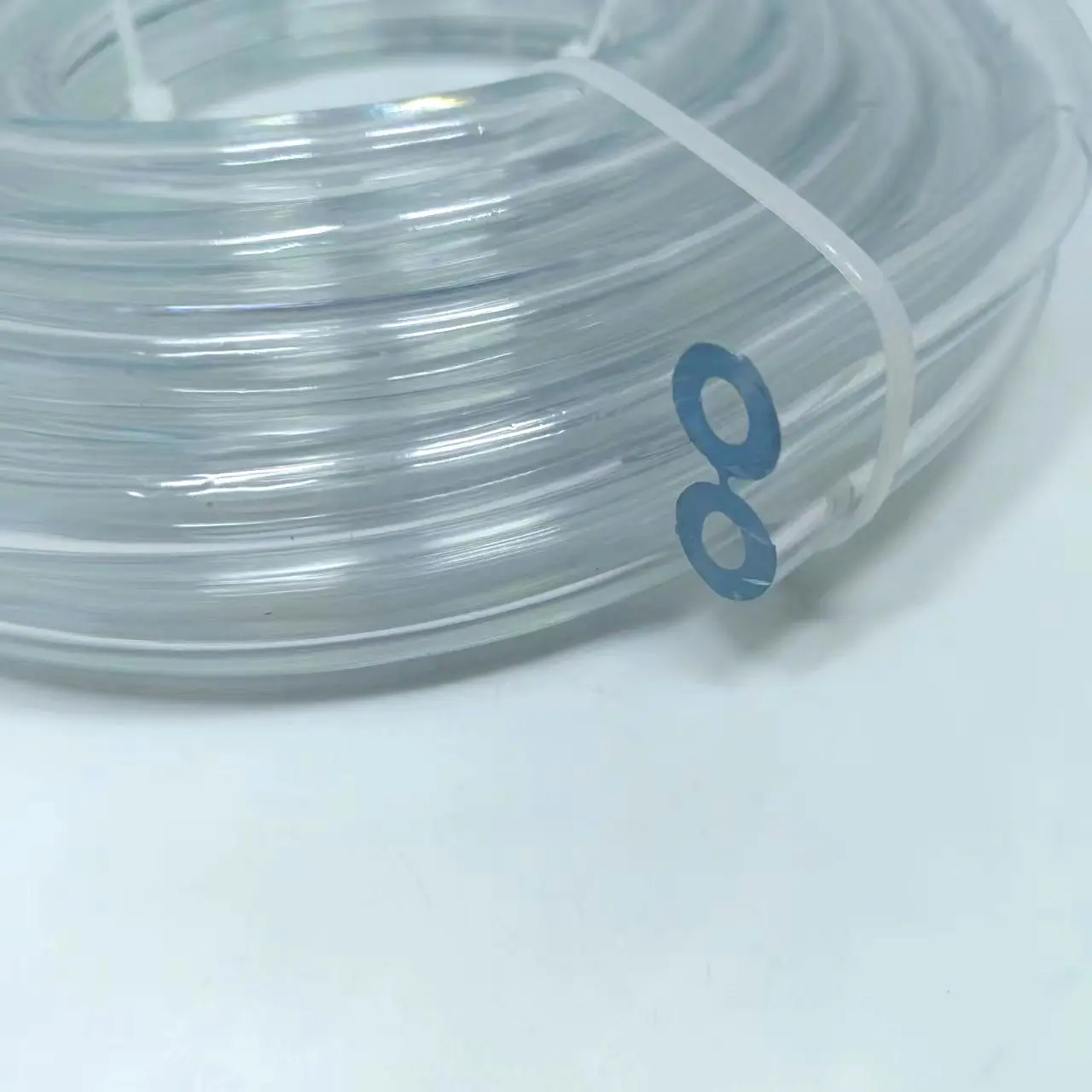

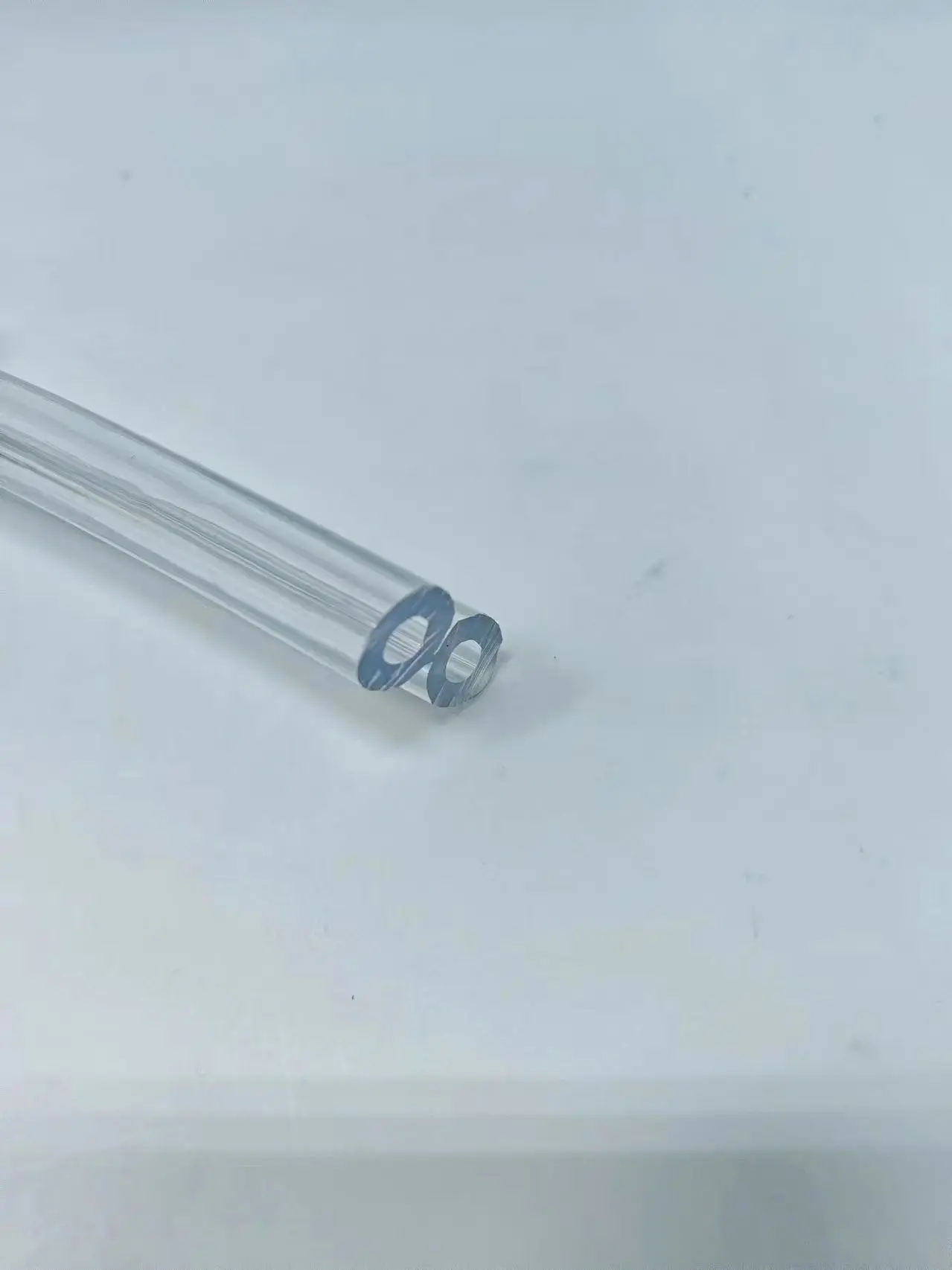

The PVC twin clear hose features a parallel dual-channel design, creating two independent flow paths within a single hose. This structure retains the visibility advantages of standard PVC clear hose while enabling simultaneous transfer of different liquids.

Made from food-grade PVC material, the hose has uniform wall thickness with a separation layer between the two channels to prevent liquid mixing. Common specifications include combinations like 6mm/8mm or 8mm/10mm inner diameters, with the overall outer diameter slightly larger than single hoses while maintaining good flexibility.

Compared to single hoses, the twin design reduces tangling issues and is particularly suitable for applications requiring concurrent transfer of two media. The transparent material allows visual monitoring of liquid flow in both channels.

The 9/32 Twin Clear Hose is a dual-channel food-grade PVC hose with transparent walls, allowing users to monitor fluid flow in real-time. Its construction ensures chemical inertness, preventing reactions with liquids like water, juice, milk, or other beverages.

Key Features:

Food Safe: Complies with FDA and EU food contact regulations

Transparency: Clear PVC allows easy visual monitoring of liquids

Twin Design: Two parallel channels for dual-fluid transfer or simultaneous flow monitoring

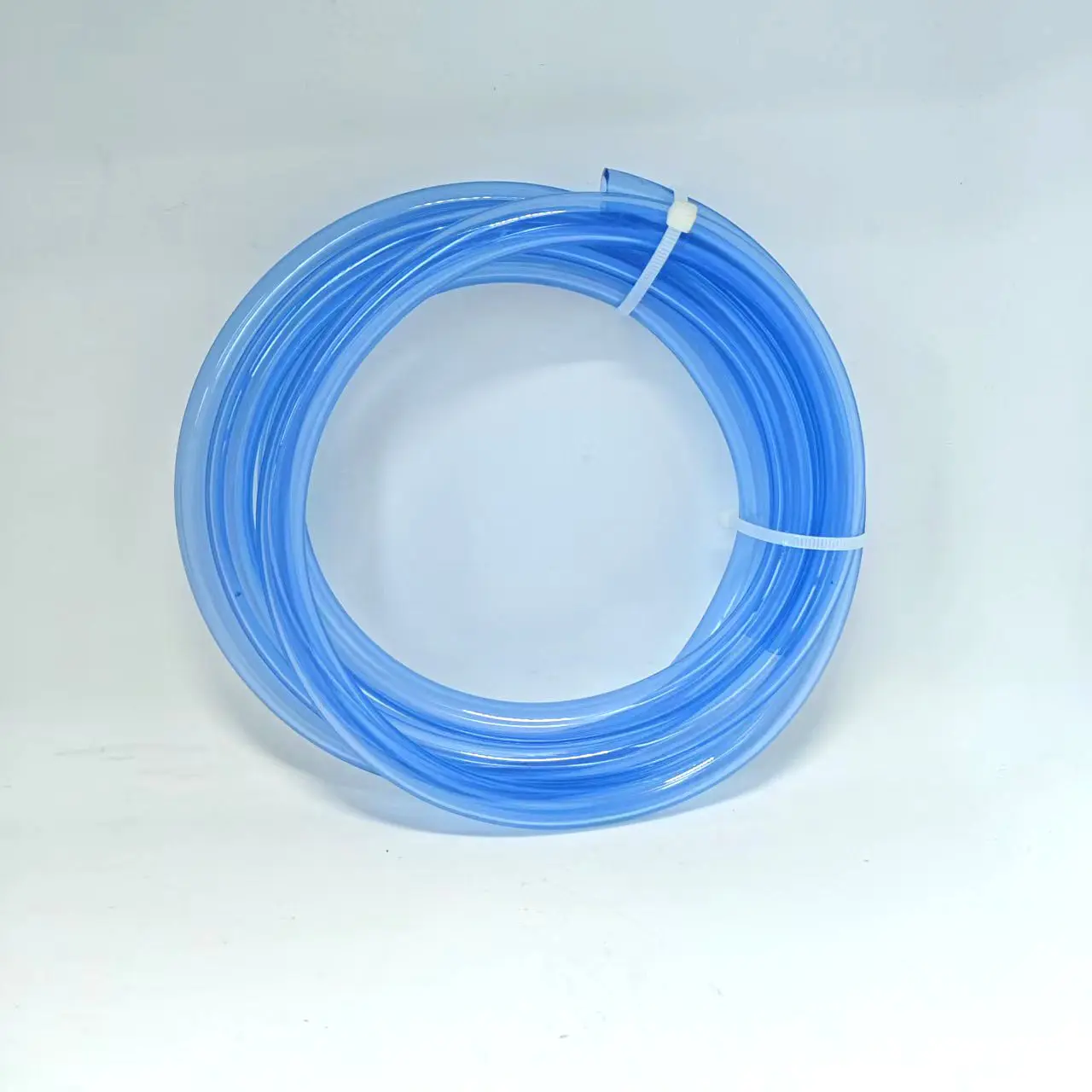

Flexibility: Lightweight and easy to route even in tight spaces

Durability: Resistant to kinking, abrasion, and mild chemicals

Applications

Food & Beverage Industry: Milk, juice, water, beer, syrups

Brewing & Distilling: Perfect for small-scale breweries and beverage lines

Laboratories: Safe transfer of consumable liquids in research and production

Home Brewing & DIY: Easy-to-use twin hose for separating liquids

Technical Specifications

| Property | Specification |

|---|---|

| Inner Diameter (ID) | 9/32 inch (~7 mm) per channel |

| Outer Diameter (OD) | ~5/16 inch (~8 mm) per channel |

| Length | Standard 25 ft / 50 ft / 100 ft rolls |

| Material | FDA-compliant clear PVC |

| Temperature Range | -10°C to +60°C |

| Pressure Rating | Up to 20 PSI (1.4 bar) |

| Reinforcement | Flexible PVC, kink-resistant |

| Transparency | High clarity for visual monitoring |

Key Features

Independent Dual Channels

Two completely isolated channels enable simultaneous transfer of different liquids without cross-contamination

Visual Monitoring

Transparent walls allow easy observation of flow rates and liquid purity in both channels

Space Saving

Replaces two separate hoses, reducing installation space requirements

Compatibility

Standard connectors ensure compatibility with most pumps and distributors

Easy Maintenance

Simpler to inspect and manage compared to multiple hose systems

Typical Applications

Food Processing

Simultaneous transfer of concentrate and purified water in beverage production

Parallel delivery of raw milk and additives in dairy processing

Medical Equipment

Dual-liquid circuit systems in dialysis machines

Reagent and cleaning solution transfer in laboratory analyzers

Agricultural Irrigation

Concurrent water and nutrient solution delivery in fertigation systems

Combined irrigation and chemical spraying in greenhouses

Industrial Cooling Systems

Inlet and return channels in cooling equipment

Dual-circuit cooling systems for small machinery

Selection Guide

| Selection Factor | Details |

|---|---|

| Channel Size Ratio | Choose based on required flow rates |

| Flexibility | Select high-flex models for frequent movement |

| Connector Compatibility | Ensure matching with existing equipment |

| Color Coding | Optional color-marked channels for easy identification |

Usage Precautions

Installation Notes

Verify channel correspondence before connection to avoid reversal

Minimum bending radius should exceed 5x hose diameter to prevent deformation

Operating Guidelines

Flush both channels with clean water before first use

Maintain temperature differences below 30°C when transferring liquids

Maintenance

Regularly inspect separation layer for leaks

Store flat or in large coils to avoid crushing

Cleaning and Care

Routine Cleaning

Flush both channels after each use, using soft brushes if necessary. For food/medical applications, monthly disinfection with 75% alcohol solution is recommended.

Long-Term Storage

Drain all liquid and store dry away from direct sunlight. Quarterly air pressure testing is advised to check separation integrity.

Bulk Purchasing Advice

When buying 9/32 Twin Clear Hose in bulk:

Determine Application: Check if the pressure and temperature ratings meet your processing needs.

MOQ: Standard factory MOQ is 500–1000 ft, but larger orders often get better pricing.

Custom Lengths & Colors: Renato can provide custom lengths, coiled rolls, or color-coded hoses for easier identification.

Certifications: Always verify FDA or EU food-grade compliance certificates for safety assurance.

Packaging: Palletized or shrink-wrapped rolls reduce shipping damage.

How to Identify High-Quality Food Grade Twin Hose

Transparency & Clarity: High-quality hoses are crystal clear, with no bubbles or discoloration.

Flexibility: Hose should bend easily without kinking.

Uniform Wall Thickness: Ensure even diameter along the full length.

Odor-Free Material: A good food-grade hose has no plastic smell, confirming non-toxic PVC.

Pressure & Leak Testing: Reputable suppliers perform 100% quality checks for leaks and burst resistance.

Why Choose Renato

Professional Experience: 20+ years producing high-quality hoses.

Food Safety Compliance: FDA, EU food contact standards.

Custom Solutions: Length, color, coiling, and OEM printing available.

Global Export Experience: Ships to North America, Europe, and Asia with secure packaging.

Conclusion:

The Food Grade 9/32 Twin Clear Hose is ideal for industries requiring safe, transparent, and flexible dual-channel fluid transfer. Whether for commercial food and beverage production, breweries, or home brewing, Renato ensures consistent quality, food safety compliance, and customizable solutions for bulk buyers.

FAQs

1. What is a Food Grade 9/32 Twin Clear Hose?

It is a dual-channel flexible PVC hose designed for safe liquid transfer in food and beverage applications, with clear walls for visual monitoring of flow.

2. What materials are used in the 9/32 Twin Clear Hose?

Made from FDA-compliant PVC, the hose is non-toxic, odorless, and safe for direct contact with consumable liquids.

3. What liquids can be safely transferred through this hose?

Water, milk, juices, beer, syrups, and other non-corrosive beverages.

Suitable for both industrial and home brewing applications.

4. What are the standard sizes of this twin hose?

Inner Diameter (ID): 9/32 inch (~7 mm) per channel

Outer Diameter (OD): ~5/16 inch (~8 mm) per channel

Lengths: Standard 25 ft, 50 ft, 100 ft; customizable upon request

5. What is the temperature range for safe use?

The hose can operate between -10°C to +60°C, suitable for most beverage processing and storage conditions.

6. What is the pressure rating of the 9/32 Twin Clear Hose?

Rated for up to 20 PSI (1.4 bar), ideal for low to medium pressure fluid transfer.

7. How can I tell if a twin clear hose is food grade?

Must be FDA or EU food contact compliant

Should have no plastic odor

Transparent, bubble-free PVC with uniform wall thickness

8. Can the hose be used in commercial or industrial applications?

Yes, it is widely used in food and beverage production lines, breweries, labs, and home brewing setups.

9. How should the hose be stored?

Store in a cool, dry area away from direct sunlight

Avoid sharp bends or heavy pressure on coiled hoses to maintain integrity

10. Why choose Renato as a supplier for the 9/32 Twin Clear Hose?

20+ years of experience producing food-grade hoses

Strict quality control: 100% pressure and leak-tested

Custom lengths, colors, and coiling available for bulk orders

Complies with FDA & EU food safety standards for global export