Introduction to PVC Clear Hose in the Canadian Context

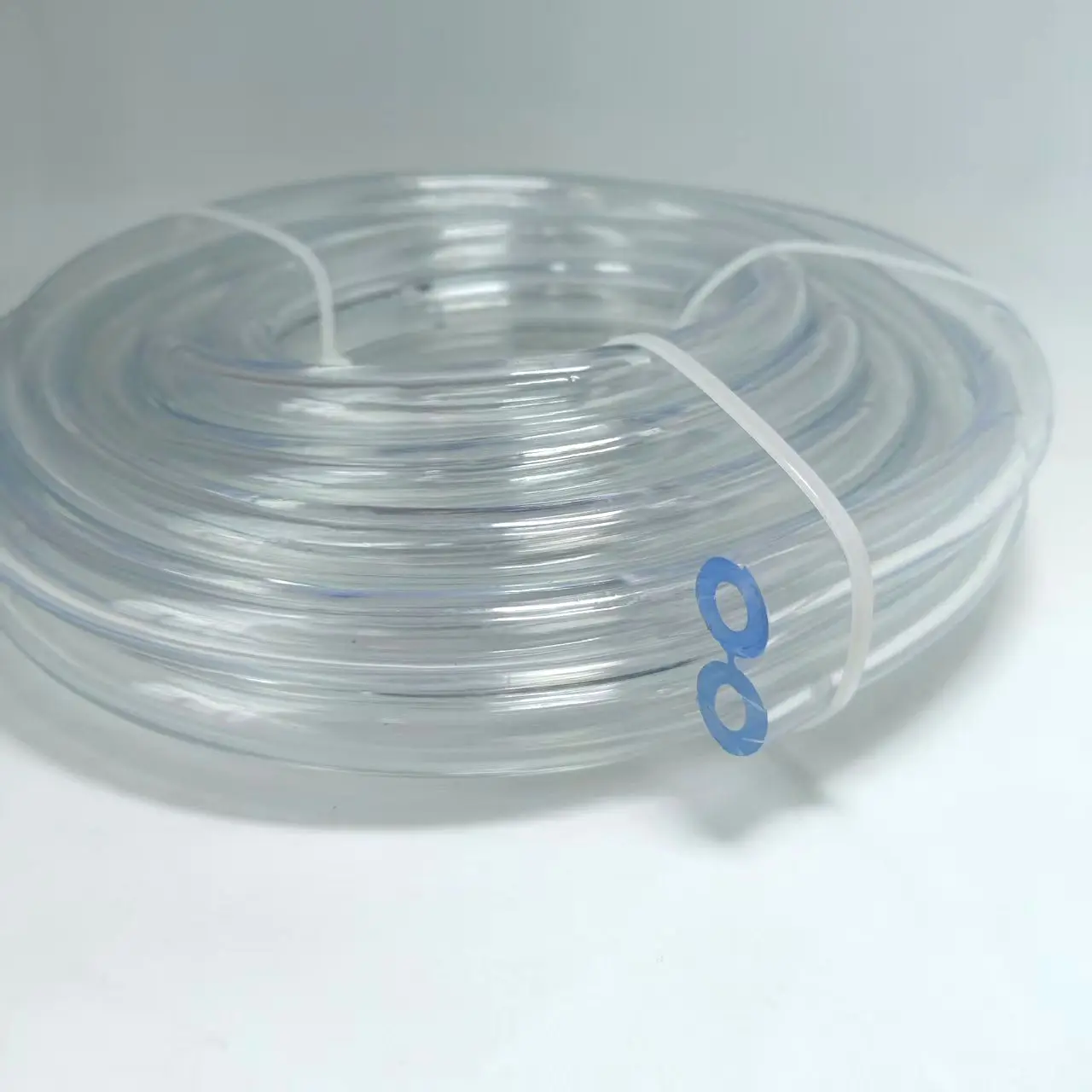

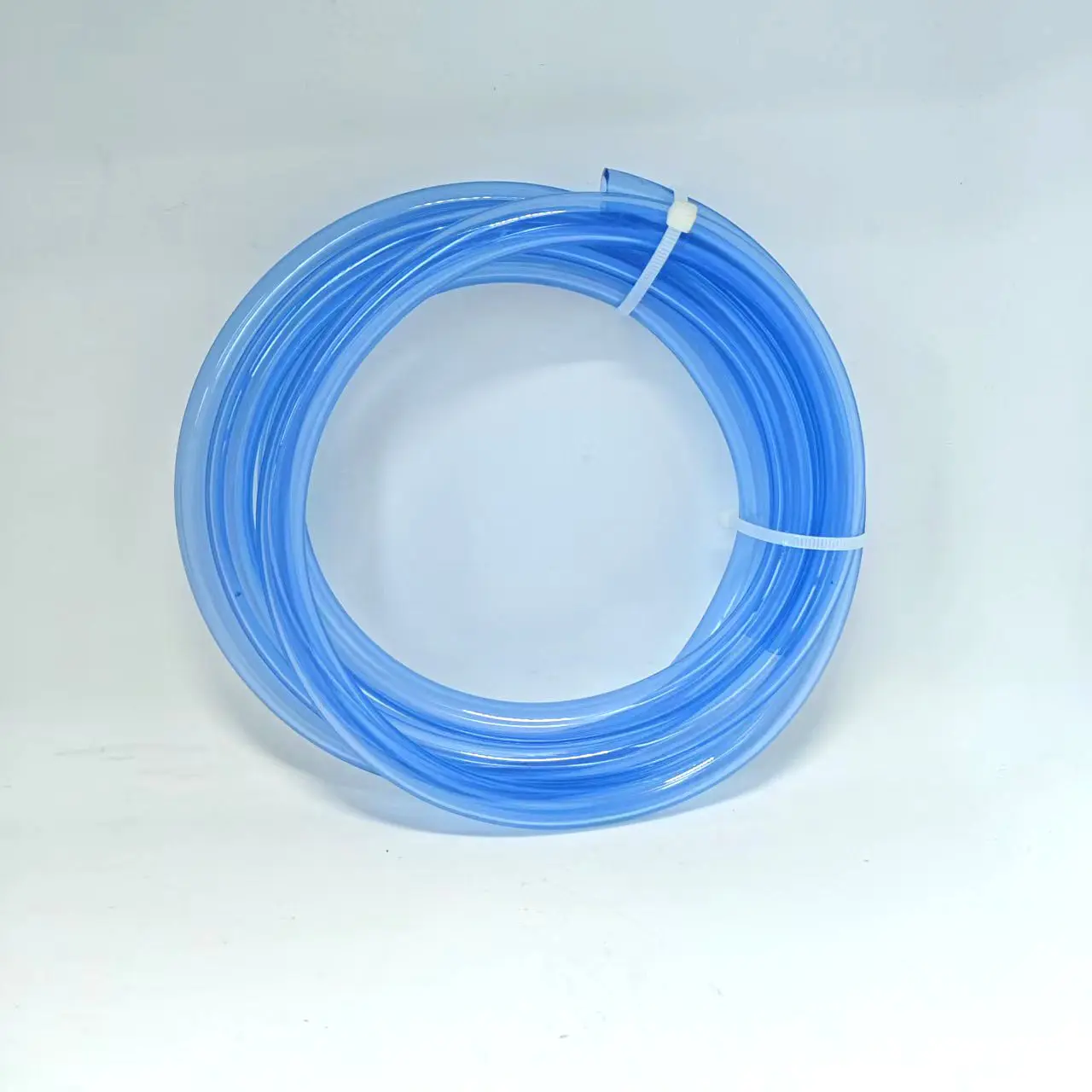

PVC clear hose has become an essential component across various Canadian industries due to its unique combination of transparency, flexibility, and cost-effectiveness. In Canada's diverse economic landscape, these hoses serve critical functions in food processing, beverage transfer, and agricultural applications, particularly where visual monitoring of liquid flow is necessary.

The Canadian market favors PVC clear hose for several practical reasons. Its lightweight nature makes it easy to handle in Canada's often challenging work environments, from dairy farms in Quebec to beverage production facilities in Ontario. The material's inherent flexibility allows for easy installation in spaces where rigid piping would be impractical, a common requirement in Canada's mixed-use industrial and agricultural settings.

What sets PVC clear hose apart in the Canadian market is its suitability for food-grade applications. Many Canadian processors and manufacturers prefer these hoses for handling milk and other beverages because they meet basic hygiene requirements while providing the visibility needed for quality control. The smooth interior surface prevents bacterial buildup when properly maintained, an important consideration in Canada's strictly regulated food production environment.

Primary Uses in Canada's Food and Beverage Sector

Milk Handling Applications

Transferring raw milk from collection tanks to processing equipment

Connecting milking machines to bulk storage containers

Moving processed milk between different stages of production

The transparency allows workers to monitor milk flow and quickly identify any contamination or consistency issues, which is particularly valuable in Canada's quality-conscious dairy sector.

Beverage Production and Transfer

Soft drink production lines

Juice transfer operations

Bottling plant applications

Syrup mixing processes

The non-reactive nature of food-grade PVC makes it suitable for these applications, provided proper cleaning protocols are followed according to Canadian food safety standards.

Other Food Processing Uses

Maple syrup collection and processing

Food ingredient transfer systems

Brewery applications for non-alcoholic components

Regional Variations in Usage Across Canada

Eastern Canada (Ontario, Quebec)

Heavy use in large-scale dairy operations

Beverage production facilities

Food processing plants

Western Canada (Alberta, British Columbia)

Smaller artisanal dairy applications

Craft beverage production

Agricultural processing

Northern Territories

Limited but important use in:

Remote community food services

Small-scale dairy operations

Beverage distribution systems

The climate differences across these regions affect hose selection, with colder areas requiring more flexible formulations to withstand low temperatures without becoming brittle.

Selection Criteria for Canadian Applications

| Consideration | Importance in Canadian Context |

|---|---|

| Temperature Range | Must withstand regional climate variations from harsh winters to hot processing environments |

| Flexibility | Needs to remain pliable in cold storage areas common in Canadian food facilities |

| Cleanability | Must accommodate Canada's rigorous food sanitation standards |

| Diameter Options | Should match common Canadian equipment specifications |

| Chemical Compatibility | Must be suitable for milk fats, sugars, and other beverage components |

Additional factors specific to Canada include compliance with voluntary food safety guidelines and adaptability to seasonal temperature fluctuations that affect viscosity of transported liquids.

Maintenance Best Practices for Canadian Conditions

Proper maintenance is crucial for PVC clear hose performance in Canada's food and beverage applications:

Cleaning Procedures

Implement regular cleaning schedules matching Canadian food processing standards

Use approved sanitizers that won't degrade the hose material

Establish visual inspection protocols to detect early signs of wear

Storage Considerations

Store in climate-controlled areas during extreme temperatures

Hang coiled hoses to prevent kinking and stress points

Protect from UV exposure when used outdoors

Replacement Indicators

Cloudiness or discoloration affecting visibility

Surface cracks or stiffness developing

Odor absorption that could affect product quality

Canadian facilities typically establish replacement schedules based on usage intensity rather than waiting for failure, especially in critical milk handling applications.

Regulatory and Safety Considerations

While avoiding specific certifications, it's important to note that Canadian users of PVC clear hose in food applications should:

Verify material safety for intended use

Ensure compatibility with cleaning protocols

Consider any provincial guidelines for food contact materials

Be aware of temperature limitations in processing environments

Many Canadian operations choose hoses that exceed basic requirements to accommodate potential regulatory changes and maintain high quality standards.

Common Challenges and Solutions in Canadian Operations

Temperature-Related Issues

Problem: Stiffening in cold processing areas

Solution: Select cold-flex formulations or implement controlled thawing procedures

Visibility Maintenance

Problem: Gradual clouding from product residue

Solution: Implement more frequent cleaning cycles

Connection Problems

Problem: Leaks at attachment points

Solution: Use Canadian-standard fittings and regular gasket inspections

Sanitation Challenges

Problem: Bacterial growth in hard-to-clean areas

Solution: Establish thorough cleaning validation processes