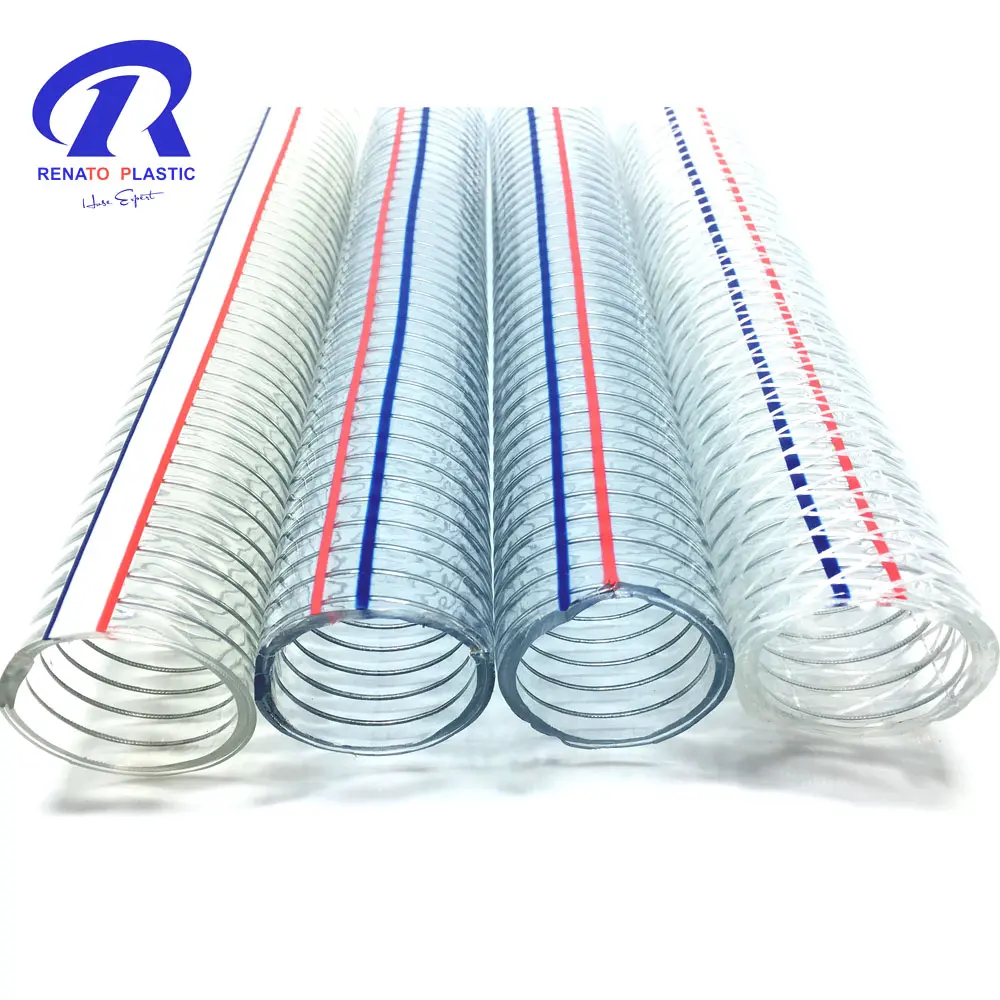

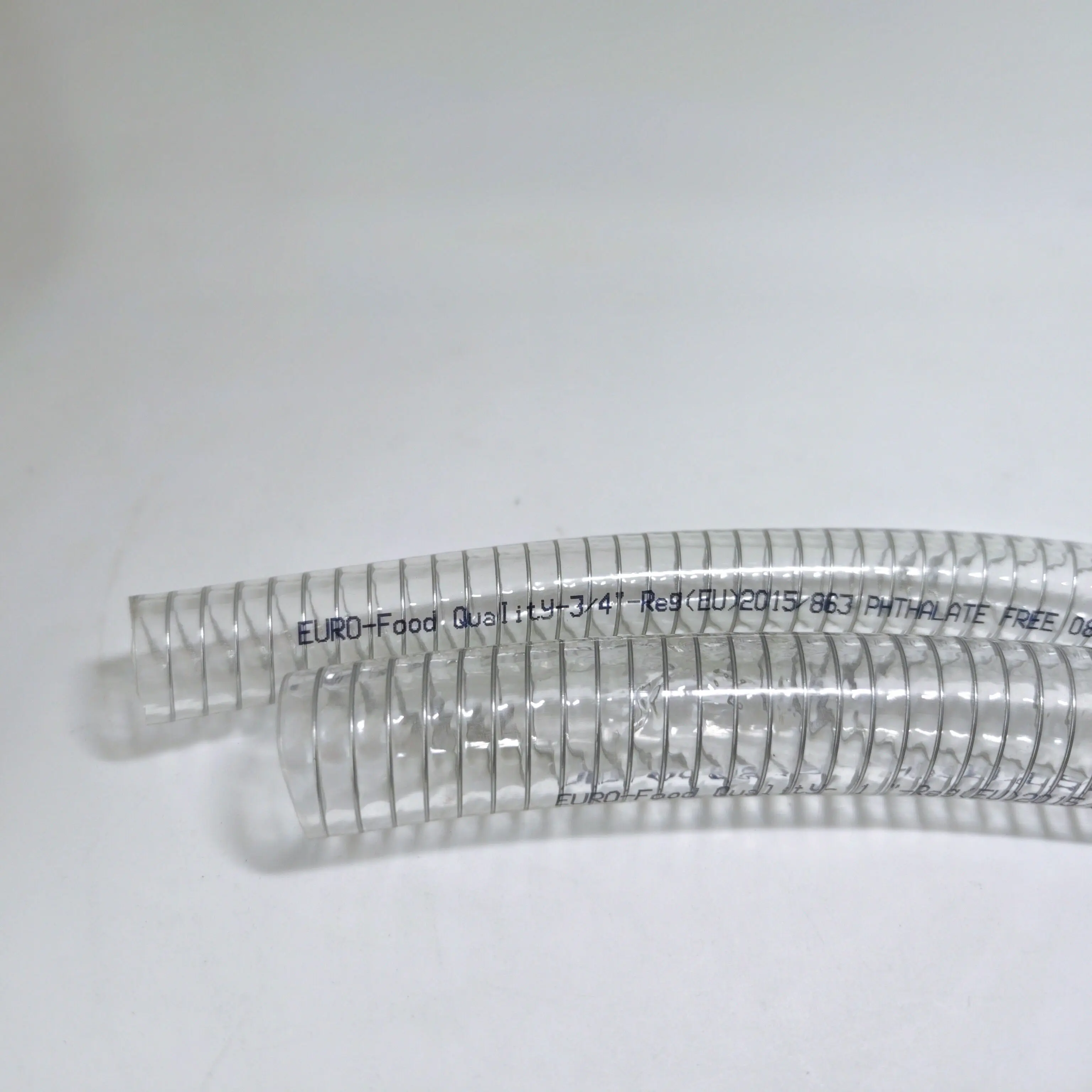

High-Performance Transparent PVC Spiral Steel Wire Hose

Qingdao Renato Plastic Co., Ltd., a leading manufacturer of high-quality PVC hoses with over 15 years of experience, presents the High-Performance Transparent PVC Spiral Steel Wire Hose. This versatile and durable hose is engineered to meet the demands of both industrial and household applications, offering unmatched reliability, safety, and efficiency in fluid transmission. Whether for transporting liquids or gases, this hose is designed to withstand extreme conditions and provide long-lasting performance.

What is PVC Steel Wire Hose

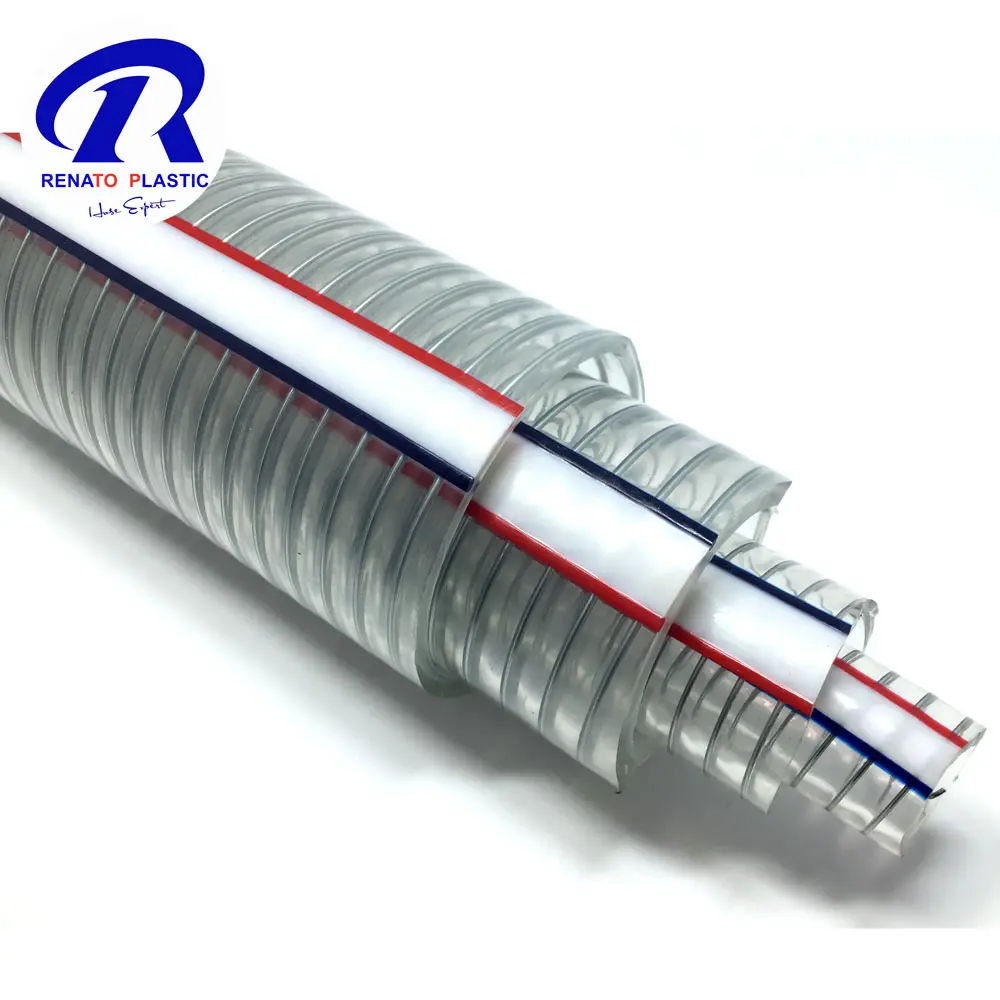

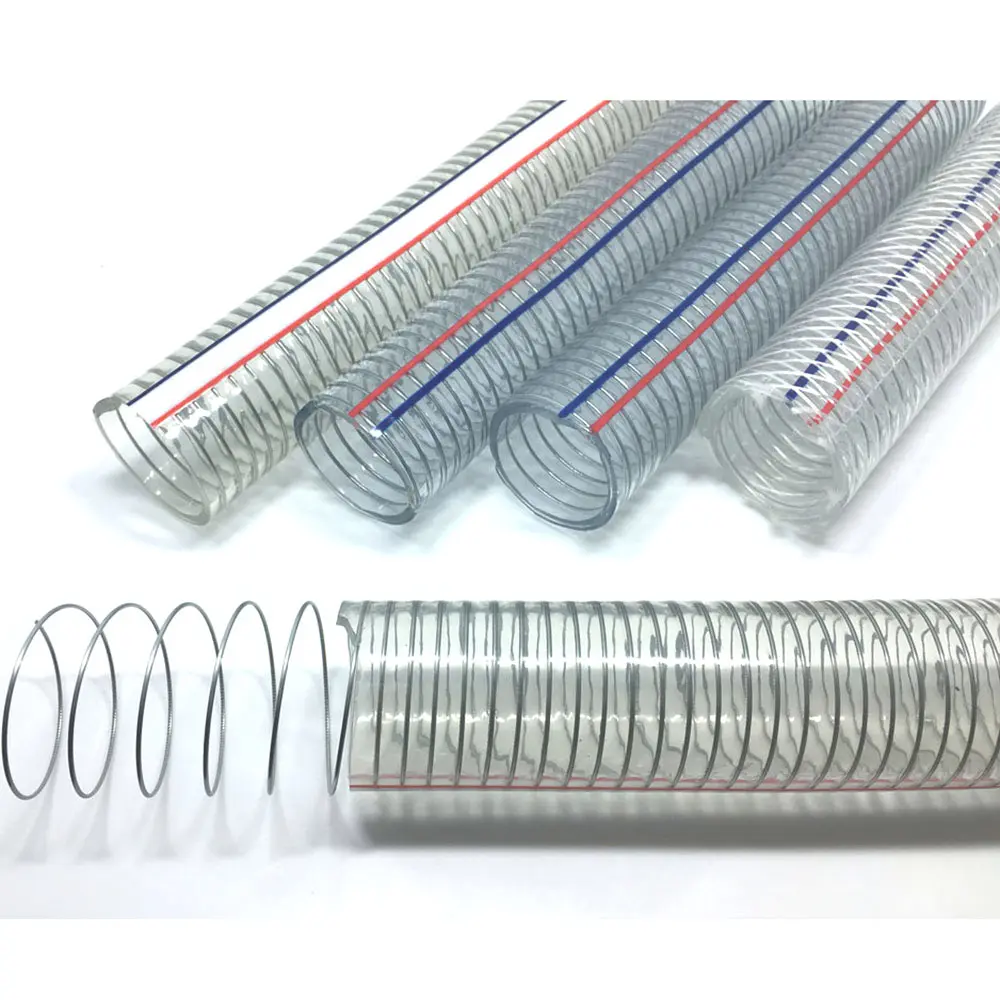

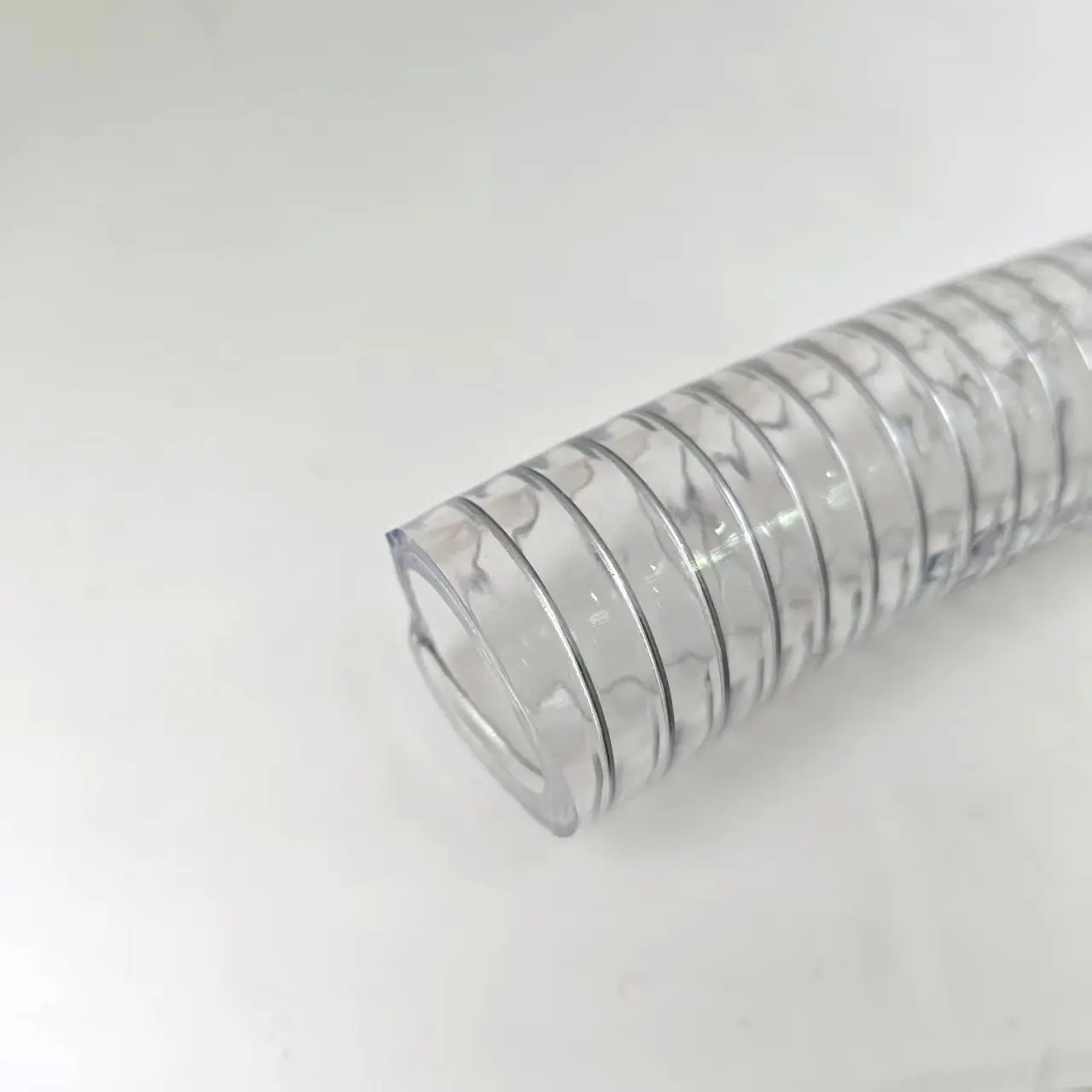

PVC Steel Wire Hose, also known as PVC reinforced steel wire hose, is a special type of tubing featuring PVC (Polyvinyl Chloride) soft plastic as its inner and outer layers, with an embedded steel wire layer in the middle for added strength. This unique design not only imparts excellent pressure resistance to the hose but also significantly enhances its tensile strength and abrasion resistance.

Specifically, the steel wire structure in PVC Steel Wire Hose can be in the form of a steel wire mesh or spiral steel wire, which effectively increases the hoop stiffness of the tubing, allowing it to withstand substantial external pressures without deforming. Furthermore, the PVC material itself is inherently corrosion-resistant and chemically inert, ensuring the hose maintains stable performance in various harsh environments.

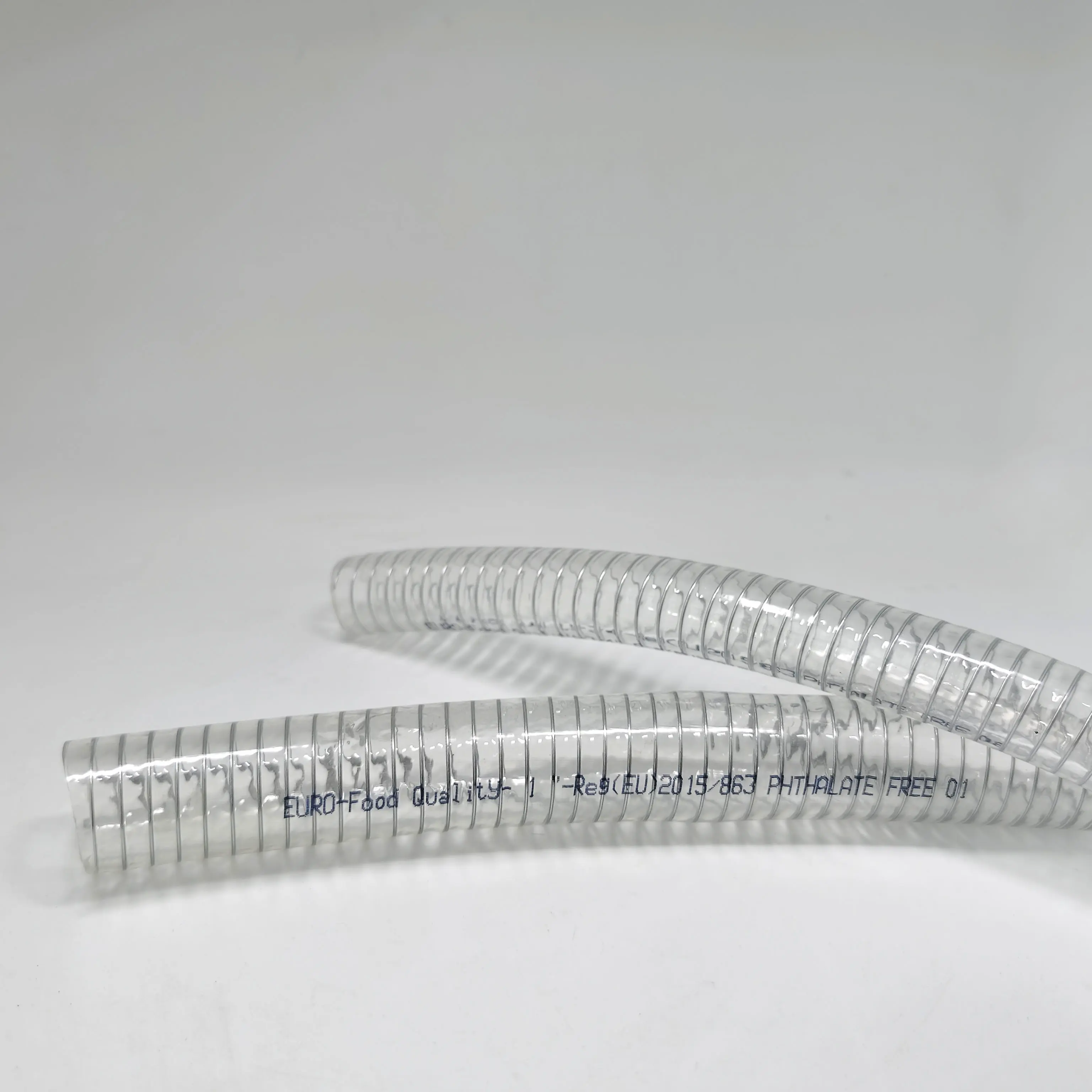

Moreover, PVC Steel Wire Hose boasts transparency, non-toxicity, and odorlessness, making it an ideal choice for applications in food, pharmaceutical, and chemical industries. For instance, in the food industry, it can be used to transport beverages, dairy products, and other liquid foods, ensuring the purity and safety of the food. In the pharmaceutical sector, it can be employed for conveying medicinal liquids or gases, catering to the specific needs of medical equipment.

In summary, PVC Steel Wire Hose, with its unique structure and outstanding performance, plays a vital role across multiple industries.

Features

High Strength and Durability: The embedded spiral steel wire reinforcement provides exceptional strength and durability, enabling the hose to withstand high pressures, kinks, and abrasions without compromising its structural integrity.

Flexibility and Ease of Handling: Despite its reinforced structure, the hose remains flexible and easy to maneuver, making it suitable for use in tight spaces and complex routing configurations.

Transparency: The transparent PVC material allows for clear visibility of the fluid or gas flowing through the hose, facilitating monitoring and troubleshooting.

Chemical Resistance: The PVC material is resistant to a wide range of chemicals, making the hose suitable for transporting various types of liquids and gases without degrading or leaching harmful substances.

Temperature Resistance: Depending on the specific PVC formulation, the hose can withstand a certain range of temperatures, making it suitable for use in both hot and cold environments.

Lightweight: Compared to other materials, PVC is relatively lightweight, making the hose easy to transport, install, and reposition as needed.

Cost-Effective: PVC is a cost-effective material, making the spiral steel wire hose an affordable solution for a wide range of industrial and commercial applications.

Versatility: Available in various diameters, lengths, and end fittings, the PVC spiral steel wire hose can be customized to meet specific application requirements.

Longevity: With proper care and maintenance, the hose can last for extended periods, reducing the need for frequent replacements and minimizing downtime.

Environmental Compatibility: PVC is recyclable, and some manufacturers offer eco-friendly options, making the hose a more sustainable choice for environmentally conscious users.

Specification Sheets

Technical Requirements

| Item | Details |

|---|---|

| Brand Name | Renflex |

| Material | PVC & Embedded Spiral Steel Wire |

| Color Options | Transparent, Black, White, Green, Red, Blue |

| Working Temperature | -30°C to +160°C |

| Working Pressure | 2 - 10 bar |

| Features | Flexible, High Negative Pressure, Excellent Chemical & Abrasion Resistance |

| Applications | Water, Powder, Granule Suction & Discharge, Transporting Water, Oil, Powder, Milk, Beer |

| Transporting Medium | Water, Oil, Powder, Granules, Beverages (Milk, Beer) |

| Certifications | RoHS, REACH, CE |

| Chemical Resistance | Yes |

| Abrasion Resistance | Yes |

| UV Resistance | Optional |

Specification Sizes

| Size (Inches) | Inner Diameter (mm) | Outer Diameter (mm) | Thickness (mm) | Length Options (m) | Working Pressure (bar) |

|---|---|---|---|---|---|

| 1/4" | 6 | 11 | 2.5 | 10 / 30 / 50 / 100 | 10 |

| 3/8" | 10 | 16 | 3 | 10 / 30 / 50 / 100 | 9 |

| 1/2" | 12 | 18 | 3 | 10 / 30 / 50 / 100 | 8 |

| 3/4" | 19 | 25 | 3 | 10 / 30 / 50 / 100 | 8 |

| 1" | 25 | 31 | 3 | 10 / 30 / 50 / 100 | 7 |

| 1 1/4" | 32 | 39 | 3.5 | 10 / 30 / 50 / 100 | 6 |

| 1 1/2" | 38 | 46 | 4 | 10 / 30 / 50 / 100 | 5 |

| 2" | 50 | 59 | 4.5 | 10 / 30 / 50 / 100 | 5 |

| 2 1/2" | 64 | 74 | 5 | 10 / 30 / 50 / 100 | 4.5 |

| 3" | 76 | 88 | 6 | 10 / 30 / 50 / 100 | 4 |

| 4" | 102 | 116 | 7 | 10 / 30 / 50 / 100 | 3.5 |

| 6" | 152 | 168 | 8 | 10 / 30 / 50 / 100 | 3 |

| 8" | 200 | 218 | 9 | 10 / 30 / 50 / 100 | 3 |

| 10" | 250 | 270 | 10 | 10 / 30 / 50 / 100 | 2.5 |

Suitable Fields and Industries

1. Industrial Sector

Fluid Transfer: In industries such as chemicals, petroleum, food processing, and pharmaceuticals, the PVC Spiral Steel Wire Hose is widely used for conveying various corrosive and non-corrosive liquids and gases. Its high pressure resistance, corrosion resistance, and wear resistance ensure the safety and stability of fluid transfer.

Equipment Connection: In factory production lines or between equipment, the hose serves as a flexible and quick connection pipeline, enhancing production efficiency and convenience.

2. Agriculture and Horticulture

Irrigation Systems: In agriculture, the hose is utilized in drip irrigation, sprinkler systems, and other irrigation methods. Its pressure resistance, weather resistance, and corrosion resistance make it suitable for complex farmland environments and varying climatic conditions.

Drainage Systems: In orchards, greenhouses, and other horticultural facilities, the PVC Spiral Steel Wire Hose is also used in drainage systems to help remove excess rainwater or irrigation water, maintaining optimal soil moisture levels.

3. Construction and Engineering

Water Supply and Drainage Systems: In construction projects, the hose is employed for indoor and outdoor water supply and drainage pipelines, particularly where frequent movement or adjustment of pipe layouts is required.

Vacuum and Compression Systems: In applications requiring vacuum or compressed air, such as vacuum cleaners and air compressors, the hose plays a crucial role.

4. Daily Life

Household Plumbing: In household plumbing systems, the hose is used to connect faucets, washing machines, water heaters, and other appliances, providing a convenient solution for water connection.

Gardens and Yards: In home gardens or yards, the hose is commonly used for watering plants, washing cars, and other daily tasks, thanks to its lightweight and durability.

5. Other Special Industries

Medical Field: Although PVC-based medical devices (such as catheters and infusion tubes) are more prevalent in the medical industry, the PVC Spiral Steel Wire Hose may find niche applications in certain medical equipment requiring high-pressure and corrosion-resistant fluid transfer systems.

Environmental Protection and Clean Energy: In the environmental protection and clean energy sectors, such as solar hot water systems and ground source heat pumps, the hose can be used to transport media or coolant fluids.

In summary, the PVC Spiral Steel Wire Hose, with its unique properties and versatile applications, plays a significant role in industries ranging from industrial, agricultural, and construction to daily life and other specialized sectors. As technology advances and markets expand, its application prospects will continue to broaden.

Usage Method

Preparation

Inspect the Hose: Before use, thoroughly inspect the hose for any damage, aging, or cracks to ensure it is in good working condition.

Prepare Tools: Gather the necessary installation tools such as hose clamps, scissors, wrenches, etc., for use during installation.

Measurement and Cutting

Measure Length: Use a tape measure to determine the required length of the hose and cut accordingly. Ensure the cut is clean and even, avoiding frayed edges.

Installation and Connection

Clean Connections: Before installing the hose, clean the fitting interfaces with a clean cloth or paper towel to remove dust and impurities.

Install the Hose: Insert the cut hose into the appropriate fitting, ensuring a tight, leak-free fit with no loose connections.

Secure the Hose: Use hose clamps or other fasteners to secure the hose in place, preventing movement or detachment during use.

Testing and Debugging

Pressure Test: After installation, conduct a pressure test to verify the hose can withstand the intended operating pressure. Follow the manufacturer's instructions during testing, and observe for leaks or deformations.

Debug and Operate: Once confirmed leak-free and pressure-resistant, commence debugging. Monitor the hose's operation and flow rate to ensure proper functioning.

Maintenance and Care

Regular Checks: Periodically inspect the hose for wear, tear, or loose connections to maintain optimal performance.

Cleaning: Keep the hose clean and dry during use. Promptly remove dirt, grease, or other contaminants from the hose's surface.

Avoid Damage: Avoid excessive bending, twisting, or pinching the hose to prevent damage or reduced lifespan.

Precautions

Follow Instructions: Strictly adhere to the manufacturer's instructions when installing and using PVC Spiral Steel Wire Hose.

Safety First: Prioritize electrical safety and fire prevention measures during operation to prevent accidents.

Select Appropriate Models and Sizes: Choose PVC Spiral Steel Wire Hose models and sizes that suit your specific needs to ensure satisfactory performance and results.

This guide outlines the basic usage method and precautions for PVC Spiral Steel Wire Hose. For further inquiries, consult a professional or refer to relevant documentation.

Company Advantages

Qingdao Renato Plastic Co., Ltd. stands out with:

Extensive Production Capabilities: Operating 10 workshops with over 60 production lines, 120 skilled workers, and a dedicated R&D team, we ensure the highest quality in every product.

Global Reach and Reputation: Our products are trusted in over 60 countries, providing dependable solutions to industries worldwide.

Quality Control Excellence: With two QC teams and a commitment to strict quality standards, we ensure that every hose meets or exceeds industry requirements.

Customer-Centric Philosophy: We are dedicated to delivering exceptional service, offering 7x24-hour quick response to all inquiries and ensuring that customer satisfaction always comes first.

Contact Us

For more information about the Clear Anti-Static PVC Spiral Steel Wire Hose with Copper Wire or to discuss your specific requirements, please feel free to reach out to us. Your inquiry will be responded to promptly by our expert team. At Qingdao Renato Plastic Co., Ltd., our philosophy is simple: "Customers are always first."