Types of suction hose

Suction hoses are designed for transferring various liquids, gases, and solids under suction (negative pressure) conditions. They are used in a wide range of industries, including agriculture, construction, mining, and manufacturing.

I believe that everyone is familiar with vacuum cleaners now, and most of my friends should have used vacuum cleaners. Vacuum cleaners have many components, including vacuum cleaner soft brushes, vacuum cleaner handles, vacuum cleaner hoses, etc. There are many types of vacuum cleaner hoses. Next, the editor will introduce them to you so that you can have a general understanding of vacuum cleaner hoses.

What is Suction hose?

Suction hoses are commonly made of nylon mesh, polyester, thermoplastic or PVC materials

Suction hoses are commonly made of nylon mesh, polyester, thermoplastic or PVC. Generally, it has a retractable design and has the characteristics of high temperature resistance, oil acid resistance, flame retardancy, insulation, free connection, and light volume.

Common parameters

The definition of vacuum hoses generally involves the following parameters:

Ventilation rate

The distance (meters) that the medium can pass per unit time (seconds). The better ventilation rate can reach 30 meters/second.

Temperature range

The common temperature range is -40℃ to +120℃, and the instantaneous temperature reaches +150℃.

Bending radius

The bending radius refers to R as shown in Figure 1 on the right. It is the (minimum) radius of the inner circle of the hose that can be bent without damage or shortening its service life. If the bending radius is less than the R value during use, the hose is likely to get kinked.

The common bending radius is 1 times the inner diameter of the hose.

Caliber, weight and pressure

Caliber refers to the inner and outer diameters of the hose, usually expressed in millimeters (mm).

Weight, usually measured in kilograms per meter.

Suction hose is generally only allowed to work in a low-pressure environment not higher than 0.05Mpa. In special cases, it will need to withstand a certain negative pressure, that is, vacuum.

The following table shows the parameter values of PVC exhaust pipes:

Here is the translated table :

| Inner Diameter (mm) | Outer Diameter (mm) | Vacuum Pressure (Bar) | Weight (kg/m) |

|---|---|---|---|

| 20 | 25 | 0.6 | 0.120 |

| 25 | 31 | 0.55 | 0.160 |

| 32 | 38 | 0.45 | 0.240 |

| 38 | 45 | 0.45 | 0.310 |

| 40 | 47 | 0.45 | 0.330 |

| 45 | 52 | 0.4 | 0.410 |

| 50 | 58 | 0.4 | 0.500 |

| 60 | 68 | 0.4 | 0.600 |

| 63 | 72 | 0.4 | 0.625 |

| 70 | 79 | 0.4 | 0.700 |

| 76 | 85 | 0.4 | 0.780 |

| 80 | 90 | 0.4 | 0.900 |

| 90 | 101 | 0.4 | 1.050 |

| 102 | 112 | 0.4 | 1.250 |

| 110 | 121 | 0.35 | 1.360 |

| 120 | 130 | 0.35 | 1.500 |

| 127 | 138 | 0.35 | 1.600 |

| 140 | 152 | 0.35 | 1.800 |

| 152 | 164 | 0.3 | 2.140 |

| 160 | 172 | 0.25 | 2.280 |

| 180 | 193 | 0.25 | 2.500 |

| 203 | 219 | 0.2 | 3.000 |

| 254 | 270 | 0.2 | 3.600 |

| 305 | 324 | 0.1 | 4.500 |

Types of suction hose

1. Types of suction hose—EVA hose

EVA hose is a special hose for vacuum cleaners. The tube wall is made of EVA (ethylene-vinyl acetate copolymer). It is ultra-light, crush-resistant, has good alkali metal and acid resistance, can float, and has a surface impedance of <10. EVA hoses are used in various vacuum cleaners, household and industrial vacuum cleaning equipment, etc. The temperature range is between -25℃ and 65℃. EVA hoses are suitable for vacuum suction of powders and particles in mining, agriculture and water conservancy, civil engineering, food, petroleum, chemical industry, sanitation and other industries, and for conveying water, oil, chemical materials, food, etc. It has a wide range of uses in farmland irrigation, mining, oil depots, sand pumping, sandblasting, food, medical* and indoor gas, powder, dust absorption and emission. EVA hoses are excellent substitutes for PVC, rubber and metal pipes.

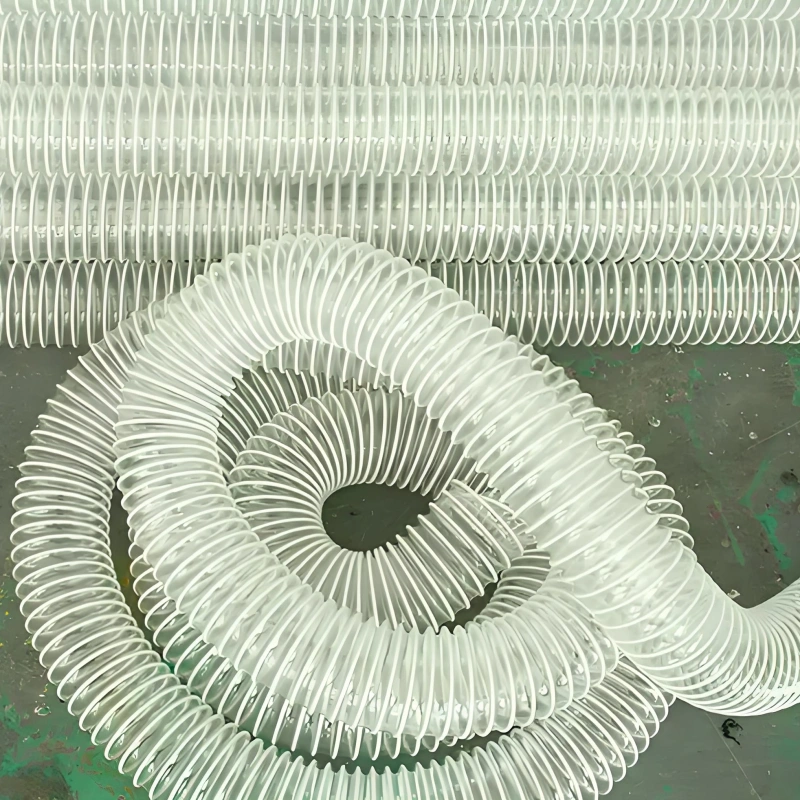

2. Types of suction hose—PU plastic reinforced spiral reinforced hose

PU plastic reinforced spiral reinforced hose is made of PU and high-strength plastic reinforced. It is light, soft, elastic, corrosion-resistant, hydrolysis-resistant, highly transparent, non-toxic and odorless, with a small bending radius and good negative pressure resistance. It can maintain its original shape under suction. It can also maintain good flexibility at extremely low temperatures, with super high strength and super long service life. The conveying medium of PU plastic reinforced spiral reinforced hose is liquid, food and beverage, oil, water, gas, solid particles. The applicable temperature of PU plastic reinforced spiral reinforced hose is between -40℃ and 90℃, and can reach 120℃ for a short time.

3. Types of suction hose—PU hose

PU hose is extremely wear-resistant, copper-plated steel wire reinforces hose strength, resistant to high pressure, vacuum and compression, superior high shaft strength, smooth conveying of materials, and good chemical resistance. The bending radius of PU hose is approximately equal to 3 times the outer diameter, which can discharge static electricity. PU hose is coated with strong and elastic copper-plated steel wire on the tube wall: the polyurethane material is extremely wear-resistant and tear-resistant, with a wall thickness of about 0.6-0.9MM and a smooth inner wall; it is more than 10 times more wear-resistant than ordinary PVC hoses and rubber hoses. The temperature range is about -40℃ to +90℃, and can reach +130℃ for a short time. PU hose is mainly used for ventilation and dust collection, for high-speed flow of highly abrasive particles, gravel, gravel, fine particles, useless glass, dust and chips, gas and liquid environments, silo transportation, and can also be used for mechanical transportation pipes in the glass industry, wood industry, steel industry, plastic industry, mines, shipbuilding industry, cement industry, etc., which can better meet the ventilation and dust collection requirements of various industries.

How to distinguish and apply PVC vacuum hoses and PU vacuum hoses

The materials used in PVC vacuum hoses and polyurethane PU vacuum hoses are both thermoplastic materials, which belong to the category of soft rubber, easy to shape, and very common in the plastic hose industry. Generally, different materials are selected according to the use factors such as temperature, chemical resistance, and wear resistance. What are the differences between the two specific vacuum hoses and how to apply them?

1. PVC vacuum hose

No plastic pipe can be perfectly applied to all industries, but it must be said that PVC hoses are currently widely used in the market, especially in the vacuum hose industry. PVC vacuum hoses have a wide range of chemical and corrosion resistance, excellent wear resistance, flexibility, and high transparency, which can clearly see the fluid in the tube. These characteristics, coupled with various structural options, such as PVC steel wire hoses, PVC plastic reinforced hoses, etc., and different available formulations such as high temperature resistant, flame retardant, anti-static hoses.

PVC vacuum hoses are not only for vacuuming, but can also be used for chemical processing, ventilation, water transportation, waste pipelines, viscous fluid handling, wet or dry food processing, beverage transportation, dairy processing, granular material transportation, air and gas supply, vacuum pipelines, pump discharge, spray systems, small engine fuel pipelines, protective sleeves, drinking water and irrigation systems.

PVC Vacuum Hose

Of course, PVC hoses are not all advantages. Some of its disadvantages are that it may harden and become less flexible when certain fluids (such as concentrated acids and concentrated bases) pass through it. Standard PVC pipes do not react well with fuels and oils; the pipes will harden and crack. Special PVC formulations are available for fuel and oil applications, such as those involving small engines.

2. PU Vacuum Hose

Polyurethane, often abbreviated as PU, PUR or TPU, combines the best properties of plastics and rubber. It provides high elongation values (stretchability) like rubber and better wear resistance than PVC. Polyurethane is naturally flexible and does not use additives to maintain its bending properties. Combining good chemical resistance with excellent weathering characteristics distinguishes polyurethane from other thermoplastics. Polyurethane is generally more resistant to pressure and vacuum applications than PVC or rubber of corresponding size. It is also more resistant to cutting than most other thermoplastics.

There are some important differences between the two basic formulations of urethanes, esters and ethers. Water will corrode ester-based polyurethanes, causing significant degradation of physical properties. Ether urethanes exhibit very superior hydrolytic stability, especially in humid environments. Ether-based materials also resist fungal growth better than ester-based materials.

Relatively speaking, polyurethane PU vacuum hoses are more wear-resistant than PVC vacuum hoses. The wear resistance of polyurethane PU is almost 3-5 times that of PVC. In addition, polyurethane PU vacuum hoses can withstand minus 40 degrees and high temperatures of 125 degrees. PVC vacuum hoses can only withstand 0 degrees and high temperatures of about 70 degrees. Wear resistance and temperature resistance are the biggest highlights of polyurethane PU hoses.

PU vacuum hose

Of course, PVC vacuum hose and polyurethane PU vacuum hose also have some common features, such as:

1. Anti-kink

Ability to be colored in solid or light colors, so that the pipe or reinforced hose remains transparent

2. Flexibility

Customization, such as thermoformed shapes, thermal bonding, braiding to increase pressure and/or heat resistance, manufacturing with harder or softer hardness, non-stock sizes.

The key differences between the two materials are:

1. Low temperature use: PVC can be used at temperatures close to -10℃/-80°C, while polyurethane can be used at temperatures close to -40℃/-125°C

2. Odor or taste, polyurethane vacuum hoses are usually odorless, while PVC vacuum hoses will have a slight odor even if the raw materials are good, and if the materials are not good, the odor will be very obvious.

3. Weather resistance: PVC may harden and discolor under certain conditions; polyurethane can handle outdoor applications well

4. Cost: The cost of PVC is generally lower than that of polyurethane