PVC vs TPU Hose: Differences, Applications, and How to Choose (2025 Guide)

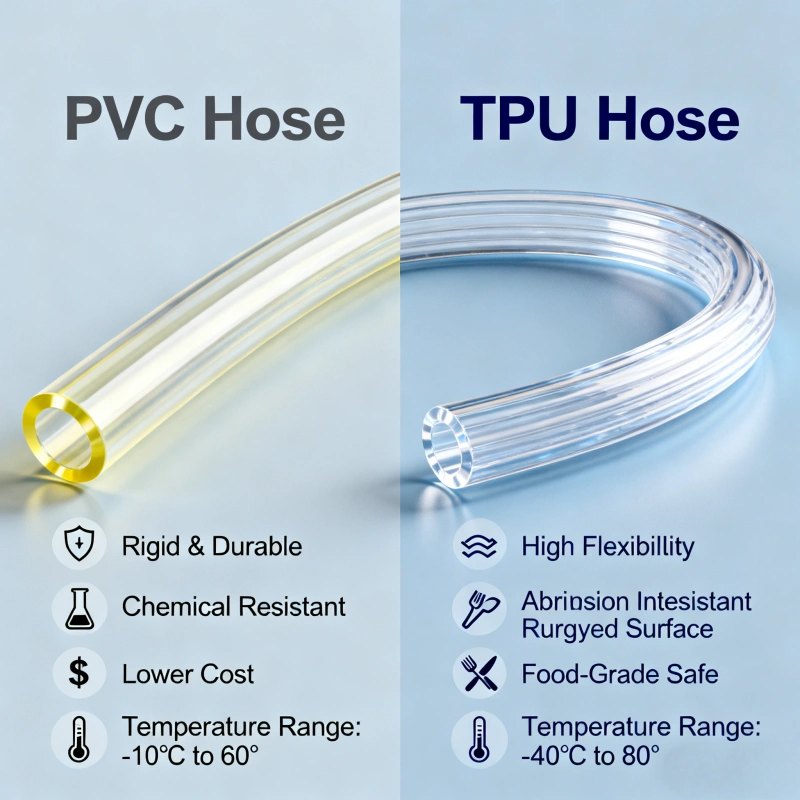

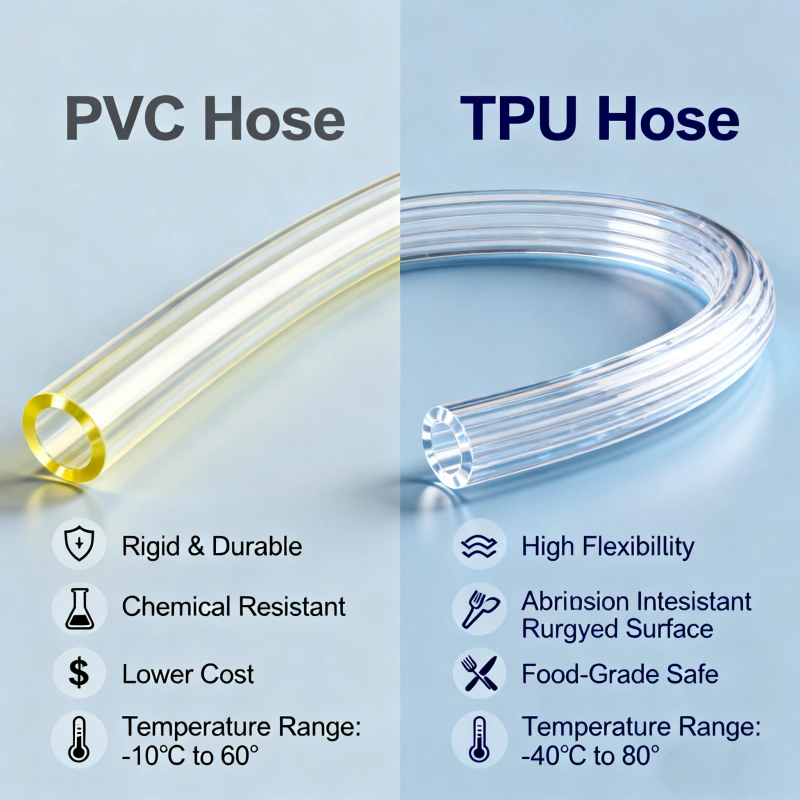

PVC (Polyvinyl Chloride) hoses and TPU (Thermoplastic Polyurethane) hoses are popular in agriculture, construction, industry, and fluid transfer systems.

They overlap in some uses, but their behavior under real-world stress is not the same. Understanding the differences helps avoid the classic “cheap hose breaks at the worst time” scenario.

What Is a PVC Hose?

PVC hose is made from polyvinyl chloride combined with plasticizers to increase flexibility. It’s widely used because it’s affordable, easy to produce, and comes in countless variations: reinforced PVC, nylon-braided PVC, lay-flat PVC, suction PVC—you name it.

Strengths: Cost-effective, lightweight, chemically resistant

Weaknesses: Stiffens in cold weather, lower abrasion resistance, weaker elasticity

PVC is the everyday worker: not fancy, but reliable as long as you keep conditions reasonable.

What Is a TPU Hose?

TPU (Thermoplastic Polyurethane) is a high-performance elastomer known for toughness, elasticity, and resistance to abrasion, oils, and weathering. TPU hoses often outperform PVC in demanding conditions such as mining, fuel transfer, robotics, and harsh outdoor environments.

Strengths: Excellent abrasion resistance, high flexibility, long lifespan

Weaknesses: Higher price, sometimes overkill for light-duty use

TPU behaves like a professional athlete—fast, strong, and highly adaptable.

Material and Performance Differences

1. Flexibility

PVC: Flexible but stiffens in low temperatures

TPU: Remains flexible in cold and hot conditions

A PVC hose at –10°C can feel like wrestling a frozen python. TPU stays supple.

2. Abrasion Resistance

PVC: Moderate

TPU: Extremely high

TPU is preferred where dragging the hose over concrete, gravel, or metal is unavoidable.

3. Temperature Range

PVC: –10°C to +60°C (varies)

TPU: –40°C to +90°C

TPU survives winter and high-pressure heat like it has no opinion about physics.

4. Chemical Resistance

PVC: Good with acids, alkalis, and some chemicals

TPU: Superior with oils, fuels, and solvents

Fuel handling almost always goes TPU.

5. Pressure Rating

PVC: Lower working pressure

TPU: Higher working pressure and burst strength

If the pump is powerful, TPU plays safer.

6. Weight

PVC: Lighter

TPU: Slightly heavier due to stronger structure

PVC wins the “carry it all day” award.

7. Lifespan

PVC: 1–3 years depending on UV and environment

TPU: 5–10 years in heavy-duty conditions

Over time, TPU often ends up more cost-effective despite the higher price.

Applications: Where Each Hose Performs Best

PVC Hose Applications

• Agriculture irrigation

• Garden watering

• Construction water discharge

• Low-pressure air supply

• Household and general-purpose use

• Light industrial fluid transfer

• Chemical transfer (non-oil-based)

• Lay-flat water pump discharge

PVC excels when budgets matter and the environment isn’t extreme.

TPU Hose Applications

• Mining and tunnel water/dust discharge

• Fuel and oil transfer

• Firefighting

• High-pressure pump systems

• Robotic automation (pneumatics)

• Abrasive material transfer

• Outdoor harsh-environment setups

• Industrial hydraulic support lines

TPU’s durability and elasticity shine in tough conditions.

How to Choose: PVC vs TPU Hose

Choosing wisely is easier when you consider real operating conditions.

Choose PVC When:

• Budget matters

• Usage is occasional

• Pressures are low to medium

• The hose won’t face heavy abrasion

• The environment is mild (no extreme cold or heat)

PVC is the practical solution for farms, daily tools, and medium-duty tasks.

Choose TPU When:

• Abrasion and drag are unavoidable

• You need high pressure and long lifespan

• Fuel, oils, or solvents are involved

• Extreme temperatures are expected

• The cost of hose failure is high (mining, fire, industry)

TPU is the premium, long-term investment.

Price Comparison (Approximate Market Range)

PVC: $0.60–$2.50 per meter

TPU: $4.00–$12.00 per meter

The price gap comes from TPU’s superior physical properties and engineering complexity.

Which One Should You Choose?

If the job is light to moderate, PVC is affordable and sufficient.

If the job is demanding, TPU pays for itself by avoiding failures, leaks, and stoppages.

PVC is like using a solid everyday sedan.

TPU is like using an all-terrain, high-performance machine that doesn't complain no matter where you take it.

Each hose has its place, and the best choice depends on the environment, lifespan expectations, and criticality of performance.

If you want a comparison table or recommendations based on your exact industry, there’s a whole universe of hose engineering quirks left to explore.