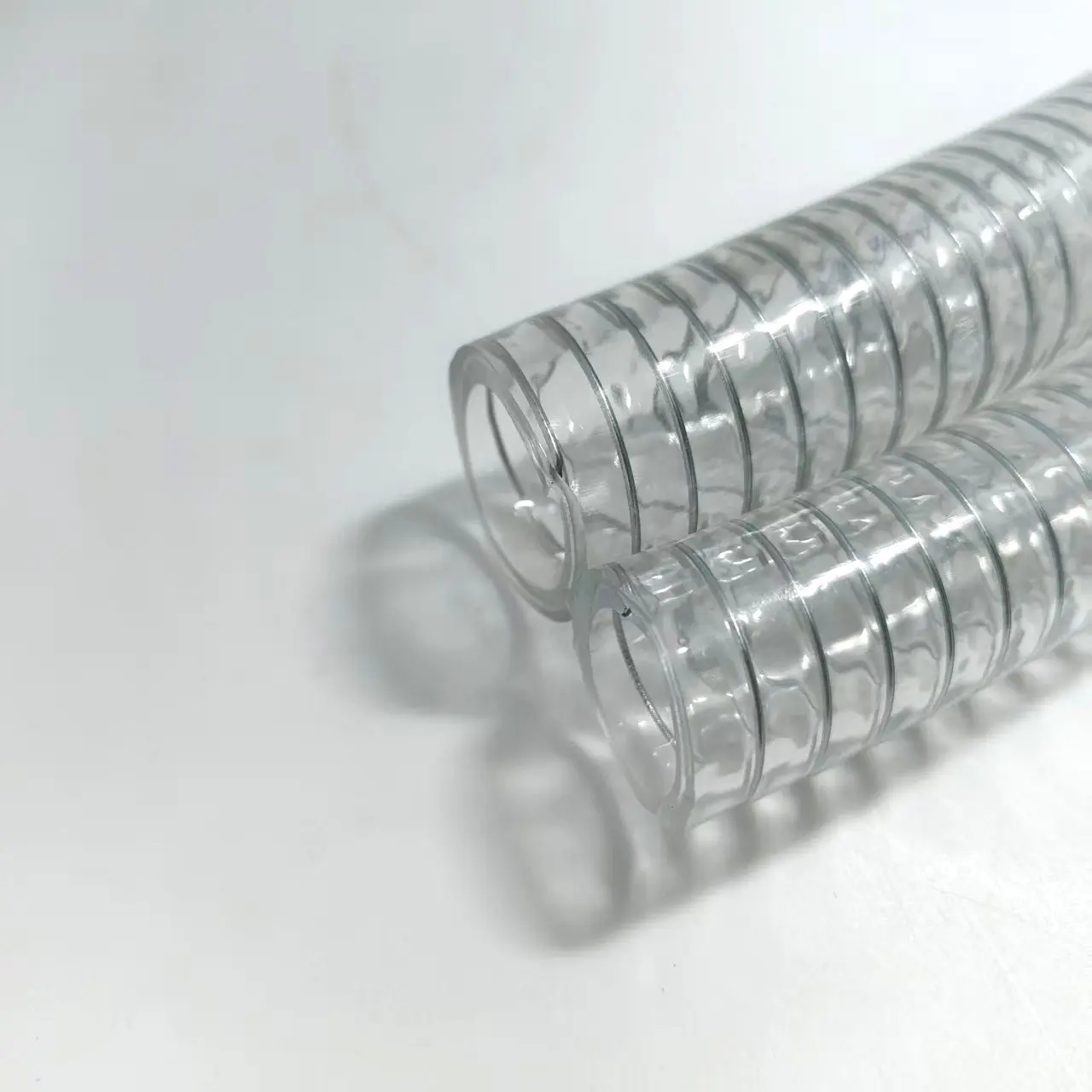

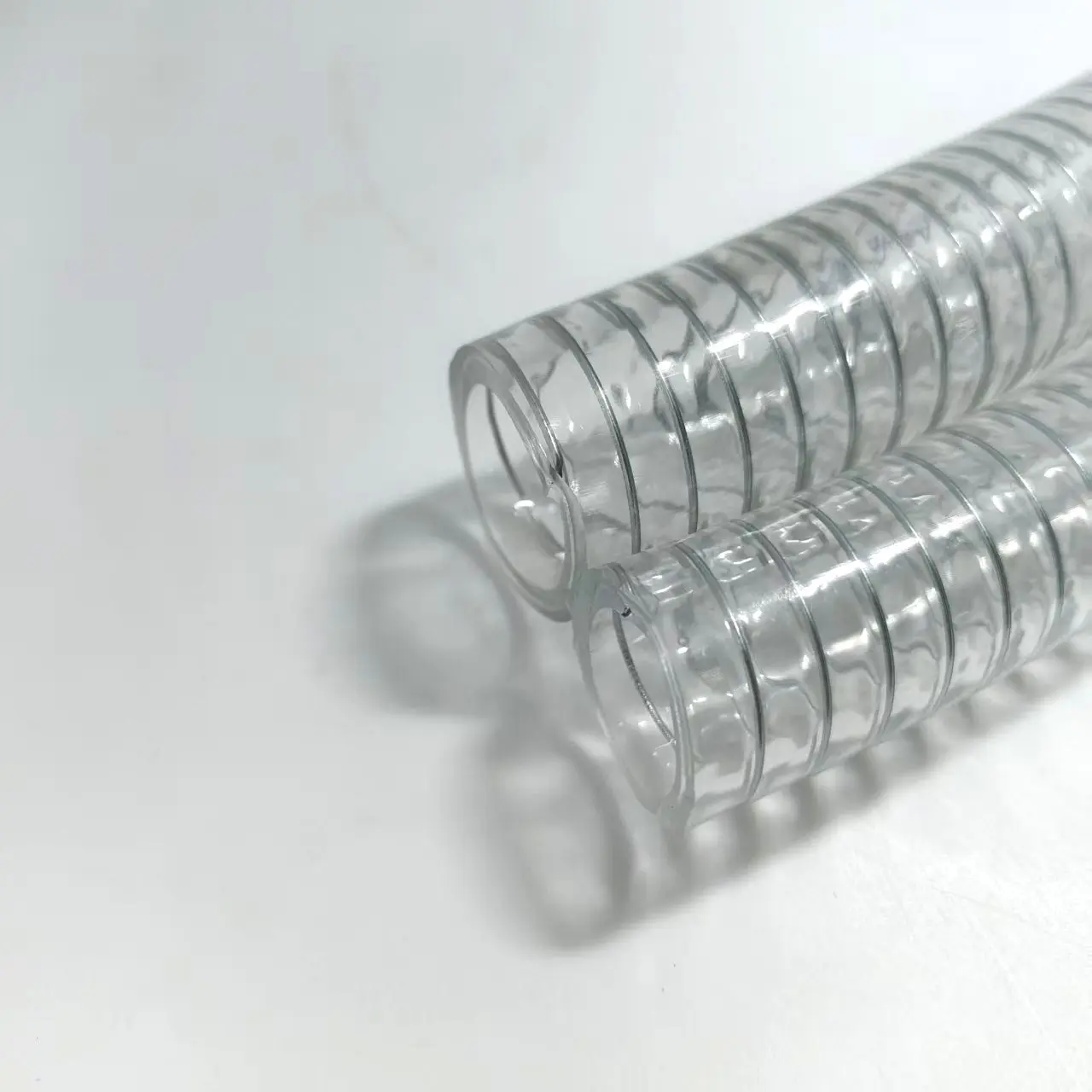

PVC steel wire hose pros and cons

Advantages of PVC steel wire hose: pressure resistance (0.3-1.0MPa), flexibility, corrosion resistance (pH 2-12), lightweight (density 1.3-1.5g/cm³); Disadvantages: not resistant to high temperatures (-10℃~+65℃), easy to age (lifespan 3-5 years).

PVC steel wire hoses (SWH) are versatile industrial hoses designed to handle high-pressure applications, combining the rigidity of PVC with the tensile strength of steel reinforcement. Widely used in agriculture, construction, and manufacturing, these hoses are favored for their durability and pressure resistance. This analysis dissects their material composition, technical specifications, lifespan, pricing dynamics, and provides actionable procurement advice for bulk buyers.

1. Material Composition: The Science Behind PVC Steel Wire Hoses

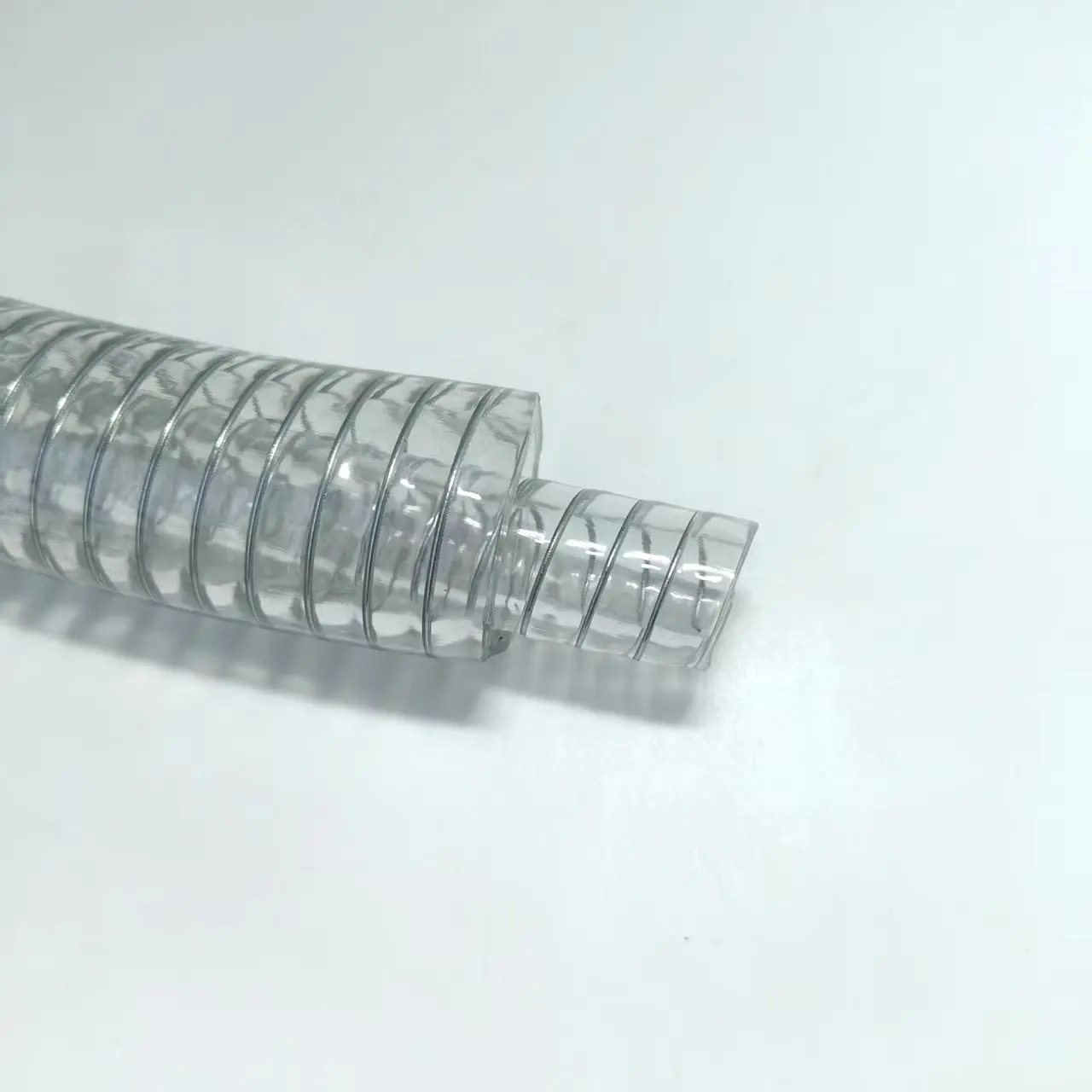

PVC steel wire hoses are composite structures engineered to balance flexibility, strength, and chemical resistance. Their design includes three critical layers:

1.1 Core Layer: PVC Resin

The inner and outer layers are made of polyvinyl chloride (PVC) resin, a synthetic polymer known for its chemical inertness, corrosion resistance, and smooth interior surface (critical for fluid flow). High-quality PVC hoses use upgraded PVC formulations (e.g., S-PVC or R-PVC) with added plasticizers (e.g., phthalates) to enhance flexibility, and stabilizers (e.g., lead, tin, or organic compounds) to resist UV degradation and thermal oxidation.

Data Point: According to ASTM D1784, industrial-grade PVC resin must have a tensile strength ≥45 MPa and elongation at break ≥200%, ensuring it withstands internal pressure without tearing.

1.2 Reinforcement Layer: Steel Wire Spiral

A helical steel wire mesh (typically 0.2–0.8 mm diameter) is embedded between the PVC layers to absorb radial pressure. The wire type (galvanized, stainless, or coated) directly impacts performance:

| Wire Type | Tensile Strength (MPa) | Corrosion Resistance | Cost Impact |

|---|---|---|---|

| Galvanized (Zinc-Coated) | 500–650 | Moderate (resists rust in dry environments) | Low (+15–20% vs. plain steel) |

| Stainless Steel (304/316) | 700–900 | Excellent (resists acids, salts, and moisture) | High (+50–100% vs. galvanized) |

| Polymer-Coated (PVC/Epoxy) | 480–620 | Good (barrier against chemicals) | Medium (+25–35% vs. galvanized) |

Example: A 1-inch (25.4 mm) PVC SWH with 0.5 mm galvanized steel wire reinforcement can handle up to 300 PSI (20.7 bar) working pressure, per ISO 1436 standards.

1.3 Middle Layer: Adhesive Binder

A thermoplastic adhesive (e.g., polyvinyl acetate or epoxy) bonds the PVC layers to the steel wire, preventing delamination under pressure. High-adhesion binders (with ≥8 N/cm peel strength, per ASTM D903) are critical for hoses used in vibrating environments (e.g., construction sites).

2. Technical Specifications: Sizing, Pressure, and Standards

PVC steel wire hoses are categorized by inner diameter (ID), wall thickness, and pressure ratings. These specs dictate their suitability for specific applications.

2.1 Common Sizes

Industrial PVC SWHs range from 1/4 inch (6 mm) to 12 inch (305 mm) in ID. The most common sizes (6–4 inch) dominate agricultural and construction markets, accounting for 70% of global demand (source: Grand View Research, 2023).

| Inner Diameter (ID) | Typical Wall Thickness | Weight per Meter (kg/m) |

|---|---|---|

| 1/2 inch (12.7 mm) | 2.5–3.5 mm | 0.25–0.35 |

| 1 inch (25.4 mm) | 3.5–4.5 mm | 0.45–0.60 |

| 2 inch (50.8 mm) | 5.0–6.5 mm | 0.80–1.10 |

| 4 inch (101.6 mm) | 7.5–9.5 mm | 1.50–2.00 |

2.2 Pressure Ratings

Performance is defined by two key metrics:

Working Pressure (WP): Maximum safe pressure during continuous use (e.g., 150–500 PSI for 1–4 inch hoses).

Burst Pressure (BP): Pressure at which the hose fails (typically 3–4x WP).

Data from a 2022 Hydraulics International test: A 2-inch galvanized steel wire PVC SWH with 0.6 mm wire diameter achieved a WP of 350 PSI and BP of 1,200 PSI. In contrast, a non-reinforced PVC hose of the same ID failed at just 80 PSI.

2.3 Compliance Standards

Industrial buyers prioritize hoses certified to:

ISO 1436: Rubber and plastics hoses and hose assemblies for automotive applications (adapted for industrial use).

SAE J517: Hydraulic hoses (for high-pressure applications).

EN 13482: European standard for wire-reinforced hoses.

3. Lifespan: Factors Influencing Durability

PVC steel wire hoses outperform non-reinforced PVC hoses but lag behind rubber hoses in extreme conditions. Their lifespan depends on:

3.1 Environmental Exposure

UV Radiation: PVC degrades under sunlight due to photodegradation, with unprotected hoses losing 30% of tensile strength after 12 months (AHMA, 2021). Hoses with UV stabilizers (e.g., carbon black or UV absorbers) extend lifespan to 5–7 years.

Temperature: PVC SWHs perform best at -10°C to 60°C. Below -10°C, PVC becomes brittle (risk of cracking); above 60°C, plasticizers leach out (softening the hose).

Chemicals: PVC resists oils, fuels, and alkalis but is vulnerable to strong acids (e.g., concentrated HCl) and oxidizers (e.g., bleach). Stainless steel reinforcement mitigates chemical corrosion.

3.2 Mechanical Stress

Abrasion: Hoses dragged over rough surfaces (e.g., gravel) experience surface wear. A 2023 test by the Industrial Hose Association (IHA) found that a 4-inch PVC SWH with a polymer-coated steel wire lasted 2x longer (500 hours) than one with uncoated wire (250 hours) under abrasive conditions.

Kinking: Sharp bends (radius < 5x ID) stress the steel wire, causing fatigue. Reinforced hoses with flexible PVC blends (e.g., PVC-P) reduce kink risk by 40%.

3.3 Lifespan Comparison Table

| Condition | PVC SWH Lifespan | Non-Reinforced PVC Hose Lifespan | Rubber Hose Lifespan |

|---|---|---|---|

| Indoor/Shaded (UV-protected) | 5–7 years | 2–3 years | 7–10 years |

| Outdoor/Sunny (UV-exposed) | 3–5 years | 1–2 years | 5–7 years |

| Heavy Abrasion (Construction) | 2–3 years | <1 year | 3–4 years |

| Chemical Exposure (Acids) | 1–2 years (non-coated wire) | N/A (rapid degradation) | 2–3 years (acid-resistant rubber) |

4. Price Analysis: Cost Drivers and Market Trends

PVC steel wire hose pricing is influenced by material quality, reinforcement type, and order volume.

4.1 Price Ranges (Per Meter)

| Specification | Entry-Level (Consumer) | Mid-Range (Industrial) | Premium (Commercial) |

|---|---|---|---|

| 1-inch ID, 0.5 mm galvanized wire | 1.5–2.5 | 3.0–5.0 | 6.0–8.0 |

| 2-inch ID, 0.6 mm stainless wire | 4.0–6.0 | 8.0–12.0 | 15.0–20.0 |

| 4-inch ID, 0.8 mm coated wire | 8.0–12.0 | 16.0–25.0 | 30.0–45.0 |

Market Data: Global PVC steel wire hose market size was valued at $1.2 billion in 2023, with a CAGR of 4.5% (2024–2030), driven by demand in emerging markets (source: MarketsandMarkets).

4.2 Cost Drivers

Steel Wire Quality: Stainless steel (316 grade) adds 2–4/meter vs. galvanized (1–2/meter).

UV Stabilizers: High-end stabilizers (e.g., hindered amine light stabilizers, HALS) increase cost by 15–20%.

Order Volume: Bulk buyers (≥1,000 meters) secure discounts of 10–15% vs. small orders (<100 meters).

5. Procurement Advice for Bulk Buyers

For industrial buyers (e.g., construction firms, agricultural suppliers), selecting the right PVC SWH requires balancing cost, performance, and application needs. Follow this framework:

5.1 Step 1: Define Application Requirements

Pressure Needs: Match WP to your system’s maximum pressure (add 20% buffer for safety).

Environment:

UV exposure: Prioritize hoses with UV stabilizers (e.g., carbon black content ≥2%).

Chemicals: Use acid-resistant PVC (e.g., chlorinated PVC, CPVC) with stainless steel wire.

Temperature: For sub-zero climates, opt for flexible PVC blends (e.g., PVC-NBR) with heated storage.

5.2 Step 2: Evaluate Material Quality

Steel Wire: Insist on galvanized (ASTM A653) or stainless (ASTM A240) wire with ≥500 MPa tensile strength.

PVC Resin: Require food-grade (FDA-compliant) or chemical-grade resin (e.g., ISO 9001-certified).

Adhesive: Test peel strength (≥8 N/cm) to prevent delamination.

5.3 Step 3: Negotiate Bulk Pricing

Volume Discounts: Aim for 10–15% off list price for orders ≥5,000 meters.

Customization: Request tailored lengths (e.g., 100m reels vs. 50m coils) to reduce waste.

Warranty: Demand a minimum 2-year warranty covering material defects (industry standard is 1–3 years).

5.4 Step 4: Test Before Full Deployment

Pressure Testing: Conduct hydrostatic tests (1.5x WP) to verify burst pressure.

Abrasion Testing: Simulate field use with a rotating drum (1,000 cycles) to assess wear.

UV Aging: Expose samples to 60°C/UV lamps for 500 hours; check for cracking (ASTM G154).

Conclusion

PVC steel wire hoses are a cost-effective solution for high-pressure, medium-duty applications, offering superior strength-to-weight ratios compared to non-reinforced hoses. However, their lifespan and performance are highly dependent on material quality and environmental conditions. Bulk buyers should prioritize:

Material Certification: Ensure compliance with ISO/SAE standards.

Environment Matching: Select UV stabilizers, chemical-resistant resins, or flexible blends based on use case.

Bulk Negotiation: Leverage volume to secure discounts and customization.

By aligning specifications with operational needs and rigorously testing samples, bulk procurement teams can maximize durability, minimize downtime, and optimize total cost of ownership.