How to Make PVC Layflat Hose: Step-by-Step Manufacturing Guide

Learn how PVC layflat hoses are made step by step — from raw PVC resin and polyester yarn to finished hose extrusion, cooling, and testing. A complete, easy-to-understand manufacturing guide for buyers and producers.

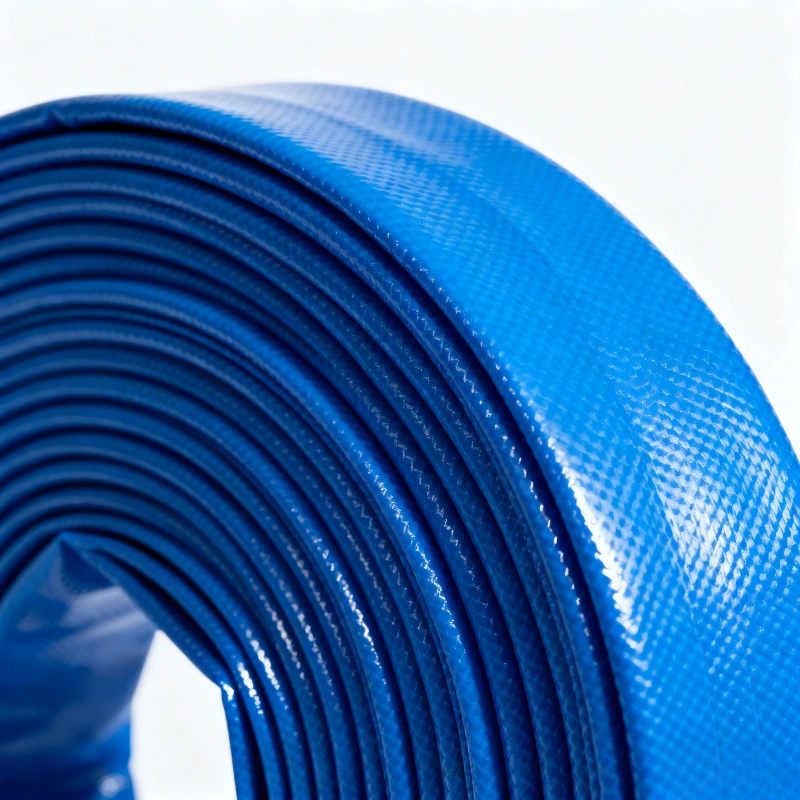

If you’ve ever seen those blue or yellow flat hoses used on farms, in construction sites, or for irrigation systems, you’ve seen a PVC layflat hose. These hoses are lightweight, flexible, and easy to store — but have you ever wondered how they’re actually made?

In this guide, we’ll break down the PVC layflat hose manufacturing process in simple terms, explain the materials and equipment used, and give you practical tips if you’re considering producing or sourcing them from China.

What Is a PVC Layflat Hose?

A PVC layflat hose is a type of flexible water discharge hose made from polyvinyl chloride (PVC) reinforced with polyester yarn.

It’s called “layflat” because it flattens when not in use and expands when filled with water.

These hoses are widely used for:

Agricultural irrigation

Water pumping and drainage

Construction and mining

Temporary water supply systems

They’re popular because they’re light, affordable, durable, and easy to transport.

Step 1: Choosing the Right Raw Materials

The main ingredients in PVC layflat hose production are:

1. PVC Resin (Polyvinyl Chloride)

The base plastic material.

Provides flexibility, chemical resistance, and water tightness.

2. Plasticizers

Added to make PVC softer and more flexible.

Common types: DOP (Dioctyl Phthalate) or eco-friendly alternatives.

3. Stabilizers

Protect the hose from heat and UV damage during production and use.

4. Color Pigments

Blue, yellow, red, or green are common colors depending on the use or brand.

5. Polyester Yarn (Reinforcement Layer)

A high-strength synthetic fiber woven into a mesh pattern.

Gives the hose its burst strength and pressure resistance.

Pro tip:

The quality of the yarn and PVC compound ratio determine how strong and flexible your hose will be.

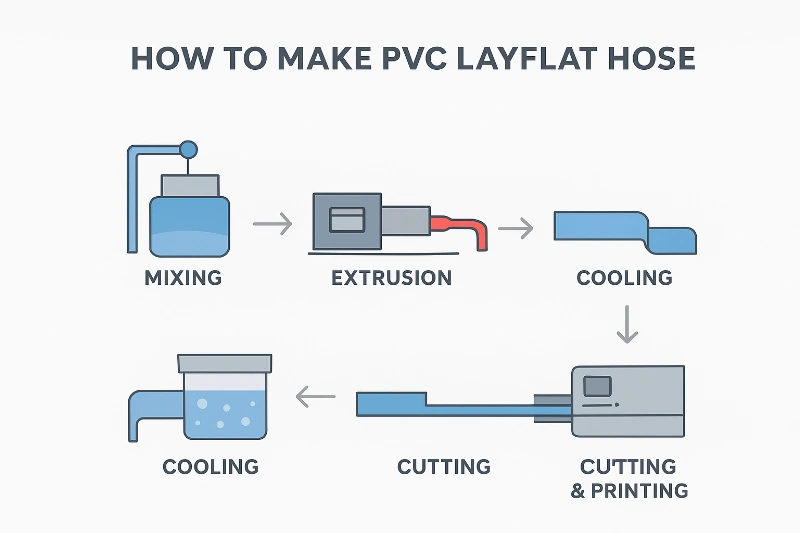

Step 2: Mixing and Compounding

All the raw materials are mixed together in a high-speed mixer to create a uniform PVC compound.

PVC resin, plasticizer, stabilizer, and color pigment are added in precise ratios.

The compound is heated to about 120–130°C (248–266°F) to ensure proper blending.

After mixing, the material is cooled and granulated into PVC pellets for easier feeding into machines.

At this stage, you have your base PVC material ready for extrusion.

Step 3: Extrusion and Yarn Reinforcement

This is where the real manufacturing happens. The extrusion line creates the hose structure.

Step 3.1: Inner Layer Extrusion

PVC pellets are melted inside an extruder (at around 160–190°C).

The molten PVC is extruded into a soft inner tube shape.

The tube passes through a cooling tank to stabilize its diameter.

Step 3.2: Yarn Braiding

The inner tube enters a braiding machine, which wraps it with high-strength polyester yarn.

The yarn forms a crisscross or spiral pattern, providing reinforcement for pressure resistance.

Step 3.3: Outer Layer Extrusion

The reinforced tube then passes through a second extruder, which coats it with an outer PVC layer.

This layer protects against abrasion, sunlight, and chemicals.

✅ Result:

You now have a three-layer PVC layflat hose:

Inner PVC tube

Polyester fiber reinforcement

Outer PVC cover

This combination makes the hose strong, flexible, and long-lasting.

Step 4: Cooling and Shaping

After extrusion, the hose passes through a water cooling tank to solidify and set its final shape.

Cooling must be gradual and even, to prevent surface wrinkles or internal stress.

The hose is kept round during cooling, ensuring that it lays flat properly when deflated.

Once cooled, the hose is air-dried and prepared for testing.

Step 5: Quality Testing

Every PVC layflat hose must go through a series of tests before shipment to ensure performance and safety.

Typical quality checks include:

| Test Type | Purpose |

|---|---|

| Burst Pressure Test | Checks how much internal pressure the hose can handle before failing. |

| Tensile Strength Test | Measures how strong the yarn reinforcement is. |

| Adhesion Test | Ensures good bonding between PVC layers and yarn. |

| Temperature Resistance | Ensures the hose won’t crack in heat or cold. |

| Flexibility Test | Checks bending performance under pressure. |

Standard working pressure ranges from 2 to 8 bar (30–120 psi) depending on size and application.

Step 6: Cutting, Printing, and Packaging

Once the hose passes testing, it’s time for finishing touches.

Cutting:

The hose is cut into standard lengths — usually 50m, 100m, or custom lengths.Printing:

Product info (brand, size, pressure rating, and batch number) is printed on the hose surface using inkjet or hot stamping.Packaging:

The hose is rolled up, tied, and packed in woven bags or cartons for shipment.

Common Sizes and Specifications

Here’s a quick guide to typical PVC layflat hose sizes:

| Diameter (inch) | Inner Diameter (mm) | Working Pressure (bar) | Length (m/roll) |

|---|---|---|---|

| 1 inch | 25 mm | 2–6 bar | 100 m |

| 2 inch | 50 mm | 2–8 bar | 100 m |

| 3 inch | 75 mm | 2–8 bar | 50 m |

| 4 inch | 100 mm | 2–8 bar | 50 m |

| 6 inch | 150 mm | 2–6 bar | 50 m |

Different applications may require customized wall thickness and reinforcement density.

Step 7: Sourcing PVC Layflat Hose or Starting Production

If you plan to buy or produce PVC layflat hoses, here are some actionable tips:

✅ For Buyers:

Buy directly from Chinese factories for the best prices and wide customization.

Check that the factory has ISO9001 certification and provides test reports.

Ask for samples and pressure test results before bulk orders.

Look for anti-UV and anti-aging additives for outdoor applications.

✅ For Manufacturers:

Invest in a stable extrusion line with precise temperature control.

Use high-quality polyester yarn and consistent PVC formulation.

Maintain strict quality inspection for each batch to build brand reliability.

Consider adding your logo and color branding to stand out in the market.

Advantages of PVC Layflat Hose

Lightweight and flexible

Easy to roll up and store

Resistant to sunlight, chemicals, and weather

Affordable and long-lasting

Customizable in color, size, and pressure rating

Final Thoughts

Now you know exactly how a PVC layflat hose is made — from raw PVC resin to a durable, flexible water hose ready for the field.

The process combines precision extrusion, yarn reinforcement, and quality control to ensure the hose can handle real-world water pressure and temperature conditions.

If you’re a buyer or business owner, sourcing PVC layflat hoses from China can save cost and guarantee consistent supply — especially when working directly with experienced factories that specialize in OEM/ODM production.

Whether you’re watering a farm or supplying construction equipment, a well-made PVC layflat hose is your best partner for reliable water flow.

Key Takeaways

Made from PVC resin + polyester yarn reinforcement

Produced via extrusion, braiding, and coating

Tested for pressure, adhesion, and durability

Widely used in agriculture, construction, and industry

Best to source from certified Chinese factories for quality and price advantages