Garden Hose Pipe Price: A Comprehensive Guide

A garden hose pipe is more than just a simple tube—its the lifeline of any home garden, enabling efficient watering of plants, cleaning of outdoor spaces, and even small-scale irrigation projects.

A garden hose pipe is more than just a simple tube—it’s the lifeline of any home garden, enabling efficient watering of plants, cleaning of outdoor spaces, and even small-scale irrigation projects. Whether you’re a homeowner with a backyard vegetable patch or a landscaper managing commercial greenery, selecting the right garden hose involves balancing durability, performance, and cost. In this article, we’ll explore what a garden hose pipe is, its technical specifications, manufacturing process, key materials (with a focus on PVC), how to spot high-quality PVC hoses, and why Renato Hose stands out as a trusted manufacturer—all while keeping price as a central consideration.

What is a Garden Hose Pipe?

A garden hose pipe is a flexible, hollow tube designed to transport water from a tap or faucet to a distant area, such as a garden, lawn, or flower bed. Unlike rigid pipes, hoses are portable and can be coiled for storage, making them ideal for intermittent use. They typically feature connectors at both ends (e.g., standard ¾-inch male/female threads) to attach to taps and nozzles, sprinklers, or other watering equipment.

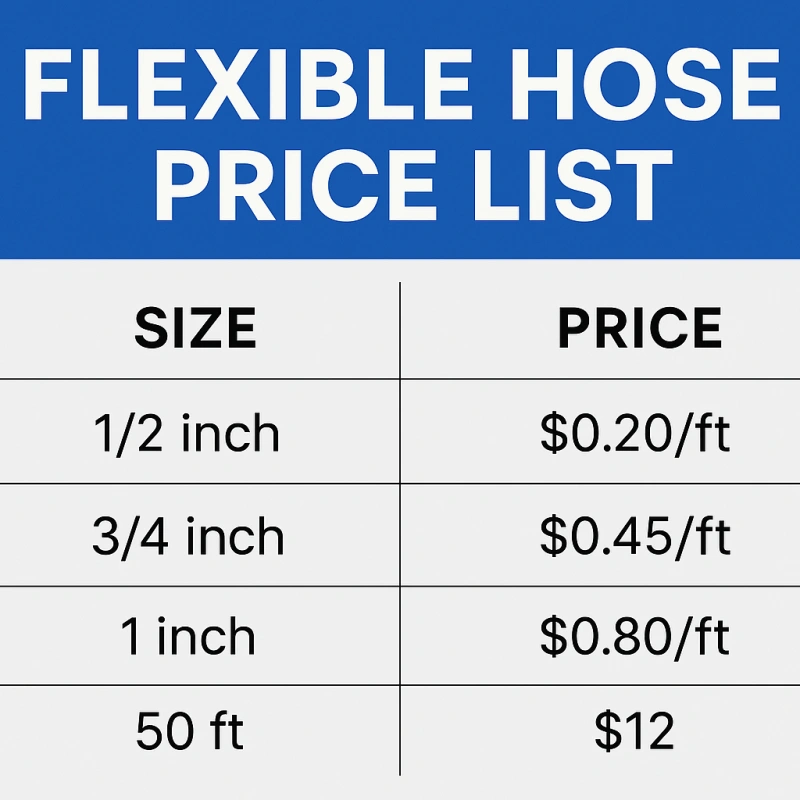

Garden hoses vary in length (ranging from 25 feet to 200+ feet), diameter (common sizes: ⅝-inch, ¾-inch, 1-inch), and pressure resistance (from low-pressure “soaker” hoses to high-pressure “sprinkler” hoses). Their primary function is to deliver water efficiently while withstanding environmental stressors like UV rays, temperature fluctuations, and physical abrasion.

Technical Specifications Table: Key Parameters of Garden Hoses

To choose the right hose, it’s essential to understand its technical specifications. Below is a table summarizing critical factors that influence performance, durability, and price:

| Parameter | Description | Typical Range | Impact on Price |

|---|---|---|---|

| Length | Total length of the hose | 25 ft, 50 ft, 75 ft, 100 ft, 150 ft, 200 ft | Longer hoses cost more due to additional material; e.g., 20–40 for 50 ft vs. 60–100 for 100 ft. |

| Inner Diameter | Diameter of the water-carrying core | ⅝-inch (most common), ¾-inch (higher flow), 1-inch (industrial/irrigation) | Larger diameters increase flow rate but raise material costs; ¾-inch hoses cost ~20% more than ⅝-inch. |

| Working Pressure | Maximum pressure the hose can withstand without bursting | 300 PSI (light-duty), 500 PSI (medium-duty), 800–1000 PSI (heavy-duty) | Higher pressure ratings require thicker walls or reinforced materials, increasing price by 30–50%. |

| Temperature Range | Optimal operating temperature range | -10°C to 60°C (standard PVC); -20°C to 70°C (UV-resistant or winterized models) | Cold-weather or UV-resistant hoses (e.g., with anti-freeze additives or UV stabilizers) cost 15–25% more. |

| Material | Primary composition of the hose | PVC (most common), PE (polyethylene), rubber, or hybrid (PVC + mesh reinforcement) | PVC hoses are affordable (20–60); rubber hoses (50–150) and hybrid models (40–80) are pricier due to better durability. |

| End Fittings | Material and design of the connector (e.g., brass, plastic, stainless steel) | Plastic (basic), brass (corrosion-resistant), stainless steel (premium) | Brass fittings add 5–15 to the hose price; stainless steel can increase it by 10–20. |

How is a Garden Hose Pipe Manufactured?

The production of a garden hose involves several stages, with the core process varying slightly based on material (e.g., PVC vs. rubber). For PVC hoses—the most common type—the manufacturing process typically follows these steps:

1. Raw Material Preparation

PVC resin (polyvinyl chloride) is mixed with additives to enhance properties like flexibility, UV resistance, and flame retardancy. Common additives include:

Plasticizers (e.g., phthalates) to keep the hose soft and flexible.

Stabilizers (e.g., lead, calcium-zinc) to prevent degradation from UV rays and heat.

Pigments (e.g., green, black) for color coding or aesthetics.

Lubricants to reduce friction during extrusion.

2. Extrusion Molding

The PVC mixture is melted and forced through an extruder machine, which shapes it into a continuous tube of the desired inner diameter (e.g., ⅝-inch). The extruder maintains precise temperature control (typically 160–200°C) to ensure the material flows evenly without bubbles or defects.

3. Reinforcement (Optional)

For heavy-duty hoses, a spiral wire (e.g., galvanized steel or polypropylene) is wrapped around the extruded tube during the extrusion process. This layer adds strength to withstand higher pressures (e.g., 800 PSI) and prevents kinking.

4. Cooling and Curing

The newly formed tube is cooled using water jets or air blowers to solidify the PVC. This step also “cures” the material, locking in the additives and ensuring dimensional stability.

5. Cutting and End Finishing

The continuous tube is cut into lengths (e.g., 50 ft, 100 ft) using automated saws. Each end is then fitted with connectors (e.g., brass or plastic fittings) via crimping, threading, or compression. High-end hoses may use double-crimping for leak-proof seals.

6. Quality Control

Final inspections check for defects like cracks, uneven wall thickness, or loose fittings. Hoses are tested for pressure resistance (using hydrostatic testing machines) and flexibility (bending tests at low temperatures).

Materials Used: Why PVC Dominates the Market

While garden hoses can be made from rubber, PE, or even fabric-reinforced materials, PVC is the most popular choice globally, especially for residential use. Here’s why:

Advantages of PVC:

Cost-Effective: PVC is cheaper to produce than natural rubber or specialized polymers, making PVC hoses accessible for budget-conscious buyers.

Lightweight: PVC hoses are easy to handle and store, reducing user fatigue during watering.

Chemical Resistance: PVC resists corrosion from water, fertilizers, and pesticides, extending lifespan.

Flexibility: With plasticizers, PVC remains flexible even in cold weather (though extreme cold can still make it brittle—hence “winterized” PVC hoses with special additives).

Limitations of PVC:

UV Sensitivity: Standard PVC degrades under prolonged sun exposure, leading to brittleness. High-quality hoses include UV stabilizers to mitigate this.

Temperature Constraints: PVC becomes rigid below 0°C (32°F) and softens above 60°C (140°F), limiting use in extreme climates.

How to Identify High-Quality PVC Garden Hoses (and Avoid Cheap Ones)

With prices ranging from 15to150, not all PVC hoses are created equal. Here are six actionable tips to spot a durable, long-lasting hose:

1. Check the Wall Thickness

High-quality PVC hoses have a consistent wall thickness (typically 1.5–3 mm for standard 50 ft hoses). Squeeze the hose—if it feels thin or uneven, it’s likely to kink or burst under pressure.

2. Inspect the Reinforcement

Heavy-duty hoses include a spiral wire (steel or polypropylene) layer. Gently twist the hose—if you feel a rigid core, it’s reinforced. Avoid “hollow-core” hoses, which are prone to collapsing.

3. Test for Kink Resistance

Bend the hose into a tight U-shape. A good hose will return to its original shape without creasing or kinking. Kinking restricts water flow and damages internal layers over time.

4. Examine the Fittings

Brass fittings (not plastic) are more durable and corrosion-resistant. Ensure fittings are tightly crimped to the hose—loose fittings cause leaks. Premium hoses (e.g., Renato Hose) use “double-crimp” technology for a secure seal.

5. Look for Certifications

Reputable brands (like Renato Hose) test their hoses against industry standards such as:

ASTM D2665 (PVC pipe standards).

UL 797 (electrical safety for heated hoses, if applicable).

NSF/ANSI 61 (safe for drinking water).

Avoid hoses without certifications—they may contain toxic additives (e.g., lead stabilizers) or fail under stress.

6. Read User Reviews

Check online reviews for feedback on durability, UV resistance, and leak issues. If multiple users report “bursting after 6 months” or “cracking in winter,” the hose is likely low-quality.

Recommended Manufacturer: Renato Hose—Quality You Can Trust at Competitive Prices

When it comes to reliable, affordable garden hoses, Renato Hose (a leading Italian manufacturer with global distribution) consistently ranks among the top choices. Here’s why:

1. Superior Materials and Craftsmanship

Renato Hose uses food-grade PVC resin with advanced UV stabilizers and anti-oxidant additives, ensuring hoses remain flexible and crack-free even after 5+ years of outdoor use. Their heavy-duty models include a triple-layer construction: an inner PVC core, a steel wire reinforcement, and an outer protective layer for added scratch resistance.

2. Wide Range of Products

Renato offers hoses tailored to diverse needs:

Residential: 50 ft/75 ft/100 ft hoses with ⅝-inch or ¾-inch diameters, priced from 25to50.

Commercial/Irrigation: 150 ft/200 ft heavy-duty hoses with 1-inch diameter and 1000 PSI rating, starting at $80.

Specialty: Soaker hoses (porous for slow watering), coiled hoses (space-saving), and heated hoses (for winter use in cold climates).

3. Stringent Quality Control

Every Renato hose undergoes 10+ quality checks, including:

Hydrostatic pressure testing (up to 150% of rated pressure).

UV exposure tests (simulating 5 years of sun damage).

Freeze-thaw cycles (-20°C to 60°C) to ensure cold-weather performance.

4. Competitive Pricing

While Renato Hose is premium, its prices are 10–20% lower than competitors like Teknor Apex or Gardena, thanks to efficient manufacturing and direct-to-consumer distribution. For example:

50 ft ⅝-inch standard hose: 28(vs.35–$40 for similar models).

100 ft ¾-inch heavy-duty hose: 55(vs.70–$80).

5. Excellent Warranty and Customer Support

Renato Hose backs its products with a 5-year limited warranty against manufacturing defects. Customers also receive free replacement fittings for the first 2 years, adding long-term value.

Garden Hose Pipe Price: Retail, Brand Wholesale, and OEM Pricing Lists (Typical Ranges)

Garden hose prices vary significantly based on material, length, brand, and features (e.g., UV resistance, pressure rating). Below is a breakdown of retail prices (consumer-facing), brand wholesale prices (dealer/retailer costs), and Chinese factory OEM prices (manufacturer’s production cost for private-label orders)—all in USD.

1. Market Retail Prices (Consumer-Facing)

Retail prices reflect end-user costs at hardware stores, home centers, or e-commerce platforms (e.g., Amazon, Home Depot). They include brand markup, marketing, and distribution fees.

| Specification | Typical Retail Price Range | Notes |

|---|---|---|

| 50 ft, ⅝-inch PVC (basic) | 15–30 | Entry-level, no reinforcement; single-layer PVC; 300 PSI rating. |

| 75 ft, ¾-inch PVC (heavy-duty) | 35–60 | Thicker walls (2.5–3 mm), steel wire reinforcement; 500–800 PSI rating. |

| 100 ft, ⅝-inch UV-resistant PVC | 40–70 | Adds UV stabilizers to prevent brittleness; 2–3 mm wall thickness. |

| 50 ft, ¾-inch rubber (premium) | 60–100 | Natural rubber core, flexible in cold weather; 1000 PSI rating. |

| 100 ft, 1-inch industrial hose | 80–150 | Large diameter, high flow rate; reinforced with polyester mesh; 1500 PSI. |

2. Brand Wholesale Prices (Dealer/Retailer Costs)

Brand wholesale prices are what distributors or retailers pay to brands (e.g., Gardena, Teknor Apex) for bulk orders. They exclude retail markup (typically 30–50%).

| Specification | Typical Wholesale Price Range | Notes |

|---|---|---|

| 50 ft, ⅝-inch PVC (basic) | 8–18 | Brands with strong marketing (e.g., Scotts) charge higher wholesale fees. |

| 75 ft, ¾-inch PVC (heavy-duty) | 20–35 | Reinforced models with steel wire; bulk orders (>1000 units) lower cost. |

| 100 ft, ⅝-inch UV-resistant PVC | 25–45 | UV additives increase production costs by ~15%, reflected in wholesale. |

| 50 ft, ¾-inch rubber (premium) | 40–70 | Rubber hoses have higher material costs (vs. PVC); wholesale markup is lower than retail. |

3. Chinese Factory OEM Prices (Production Cost)

Chinese factories (e.g., Renato Hose, Yuhong) produce OEM hoses for global brands. Prices depend on order volume, material, and complexity.

| Specification | OEM Price Range (Per Unit) | Notes |

|---|---|---|

| 50 ft, ⅝-inch PVC (basic) | 3–8 | Small orders (<5000 units): 5–8; bulk (>10,000 units): 3–5. |

| 75 ft, ¾-inch PVC (reinforced) | 6–12 | Steel wire reinforcement adds ~2/unit;5000+units:6–$8. |

| 100 ft, ⅝-inch UV-resistant PVC | 7–14 | UV stabilizers increase material cost by ~1.5/unit;bulkordersreduceto7–$10. |

| 50 ft, ¾-inch rubber (premium) | 10–18 | Rubber costs 2–3x PVC; 10,000+ units: 10–12. |

Conclusion: Balancing Price and Performance

A garden hose pipe is a practical investment—choosing the right one depends on your needs (length, flow rate, climate) and budget. PVC hoses, led by manufacturers like Renato Hose, offer an optimal balance of affordability, durability, and performance. By understanding technical specifications, inspecting key features (wall thickness, fittings, certifications), and prioritizing reputable brands, you can avoid cheap, short-lived hoses and enjoy reliable watering for years to come.

Whether you need a basic 50 ft hose for a small garden or a heavy-duty 200 ft model for commercial use, Renato Hose delivers quality at a price that won’t break the bank—proving that great value doesn’t mean compromising on performance.