Antistatic PVC Hose Price Analysis: Why Is It More Expensive Than Ordinary PVC Pipe

Antistatic PVC hoses are more expensive than ordinary PVC pipes due to their specialized materials, manufacturing complexity, and strict safety standards. This article analyzes pricing, key differences, and global trends, with insights from QINGDAO RENATO PLASTIC CO., LTD—a trusted Chinese manufacturer with over 15 years of experience in industrial hose solutions.

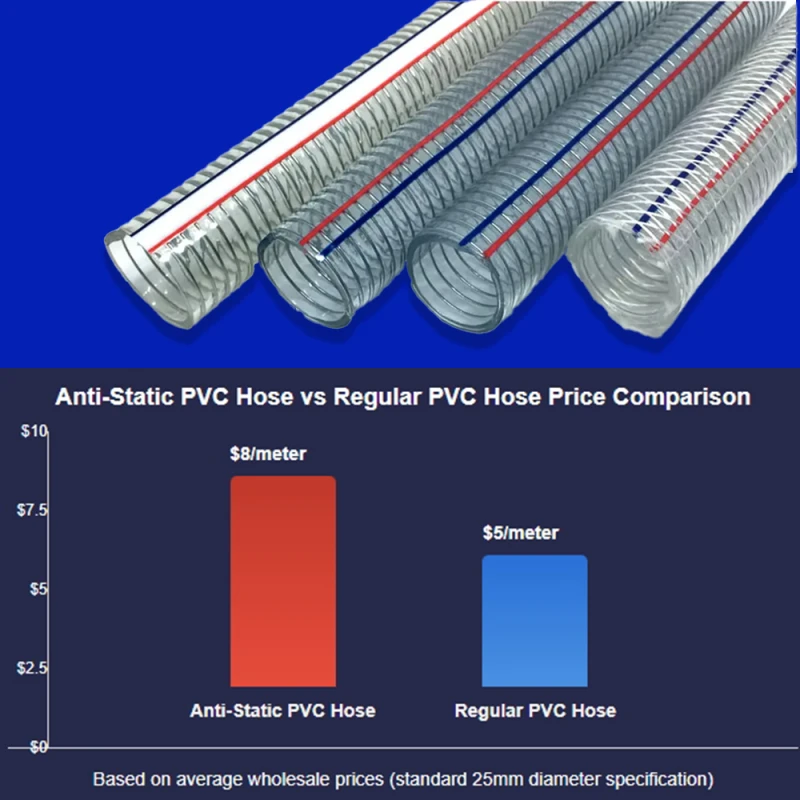

When customers first see the price tag on antistatic PVC hoses, the common response is: Why is it so much more expensive than regular PVC pipe? After all, to the untrained eye, they often look very similar—both are plastic, flexible (in some cases), and commonly used in industrial settings. But behind that visual similarity lies a web of technical differences, specialized materials, enhanced safety features, and compliance requirements that drastically change the game.

This article breaks down the real cost structure of antistatic PVC hoses versus ordinary PVC pipes, using technical insights, market data, and real-world application comparisons. As a professional PVC hose manufacturer, QINGDAO RENATO PLASTIC CO., LTD is committed not only to quality manufacturing but also to helping users understand the “why” behind pricing.

The Role of Antistatic PVC Hoses in Industrial Applications

Antistatic PVC hoses are primarily used in high-risk environments where static electricity build-up could lead to ignition, explosion, or equipment failure. We're talking industries like:

Petroleum transfer

Chemical handling

Dust collection

Mining operations

Grain and powder transportation

In these settings, using a standard PVC hose without anti-static capabilities is not just a matter of performance—it's a serious safety hazard.

Ordinary PVC pipes, on the other hand, are mostly used for water distribution, drainage, and basic fluid transport—applications where static discharge is rarely a concern.

So before even looking at materials or labor, it's important to recognize that the application determines the complexity, and complexity drives cost.

Key Technical Differences Between Antistatic PVC Hoses and Regular PVC Pipes

| Feature | Antistatic PVC Hose | Ordinary PVC Pipe |

|---|---|---|

| Material Composition | PVC + antistatic agent, conductive additives | Standard PVC |

| Reinforcement | May include steel wire, fiber, or helix structure | None or minimal |

| Surface Resistance | <10⁹ ohms (for static discharge) | >10¹² ohms |

| Target Application | High-risk (chemical, flammable materials) | General plumbing, water flow |

| Compliance Requirements | ATEX, ISO, OSHA certifications | Minimal or none |

| Flexibility | Often higher, multi-layered | Rigid or semi-flexible |

| Cost per meter (avg.) | $1.80–$4.50 | $0.50–$1.50 |

The use of conductive additives, such as carbon black, and embedded grounding wires in antistatic hoses greatly elevates the manufacturing complexity. These additions may seem subtle, but they shift the product from a “plastic tube” to an engineered safety device.

What Drives the Price Higher?

Let’s unpack the actual cost elements that make antistatic hoses more expensive:

a) Material Cost

The PVC resin used in antistatic hoses is not the same as in regular pipes. To provide static dissipation, it must be blended with conductive materials, which are 2–3x more expensive than regular additives. For instance, carbon black is commonly used for conductivity and requires precision blending.

According to market data, conductive compound prices range from $2.50–$6.00 per kg, depending on quality and supplier origin.

b) Advanced Manufacturing Process

Manufacturing antistatic hoses isn't just about extrusion. It involves:

Multi-layer extrusion

Steel wire or fiber reinforcement winding

Quality control on resistivity testing

Special curing stages to lock antistatic agents

These processes require more time per meter, specialized machinery, and trained technicians.

c) Testing and Certification

Unlike regular pipes that may pass a basic pressure test, antistatic hoses must conform to specific electrostatic dissipation standards. In Europe, this includes ATEX directives; in the U.S., OSHA and NFPA codes apply.

Certification alone can add 5–15% to the total cost depending on regulatory needs.

Cost Comparison Case Study

Let’s take a typical industrial setup needing 100 meters of hose. Below is a basic cost comparison:

| Item | Antistatic PVC Hose | Ordinary PVC Pipe |

|---|---|---|

| Price per meter | $3.50 | $1.00 |

| Total Material Cost | $350 | $100 |

| Testing & Certification | Included | Not applicable |

| Installation Tools | Grounding tools required | Basic |

| Safety Risk if Misused | Low (designed for safety) | High (fire/explosion hazard) |

In industries where dust particles, solvents, or fine powders are present, a small spark could lead to disaster. So paying $250 more upfront may prevent catastrophic losses later.

The Hidden Costs of Choosing Ordinary PVC in Risky Applications

It’s tempting for cost-conscious procurement managers to ask, “Can we just use the regular PVC pipe?” But this comes with hidden dangers:

Insurance violations: Many industrial insurers mandate the use of antistatic materials.

Downtime from explosions or fires

Legal liability: If an accident is traced to inappropriate piping, legal consequences follow.

Product contamination: In food or pharma environments, static buildup can attract dust and microbes.

Simply put, you save pennies now but risk dollars—or lives—later.

Global Market Trends and Pricing Forecasts

According to a recent report from Markets and Markets:

The global antistatic hose market is expected to grow from $890 million in 2023 to $1.36 billion by 2028, with a CAGR of 8.8%.

Factors driving this surge include:

Increased automation and pneumatic systems in manufacturing

Stricter safety regulations

Rise in flammable material handling in logistics

Regional Pricing Snapshot (2025 Q2)

| Region | Avg. Price (per meter) |

|---|---|

| North America | $3.80 |

| Europe | $4.20 |

| Southeast Asia | $2.70 |

| Middle East | $3.20 |

| China (domestic) | $2.60 |

Prices are expected to rise 5–10% annually due to raw material shortages and increased demand.

Why QINGDAO RENATO PLASTIC CO., LTD Offers Competitive Advantage

As a long-established manufacturer with over 15 years of experience, QINGDAO RENATO PLASTIC CO., LTD stands at the forefront of antistatic hose production. Here’s why we consistently outperform:

In-house blending of PVC compounds, ensuring superior conductivity control

State-of-the-art production lines (60+), minimizing downtime and maximizing consistency

Custom hose assemblies, including Camlock, Storz, and clamp fittings tailored to customer needs

Strict quality control with 2 dedicated QC teams and on-site resistivity testing

We’ve served customers in over 60 countries, with proven application success in agriculture, construction, chemical transport, and mining.

And more importantly—we respond 24/7, because we know in your world, time is pressure.

Final Thoughts: Value Over Cost

So, is the antistatic PVC hose more expensive? Yes. But is it overpriced? Absolutely not.

What you’re paying for isn’t just a hose—you’re buying protection, precision, compliance, and peace of mind. In high-risk applications, the margin for error is razor-thin. That $2.50/meter difference could mean avoiding millions in losses—or worse, preventing injuries and saving lives.

In a market that demands both performance and responsibility, cutting corners with ordinary PVC is a false economy.

Get in Touch With a Reliable Hose Partner

If you're ready to upgrade your system with safe, durable, and cost-effective antistatic PVC hoses, look no further.

QINGDAO RENATO PLASTIC CO., LTD

Whether you need a customized hose assembly, bulk order pricing, or technical support, your inquiry will be replied to the first time—because our philosophy is simple: Customer is always first.