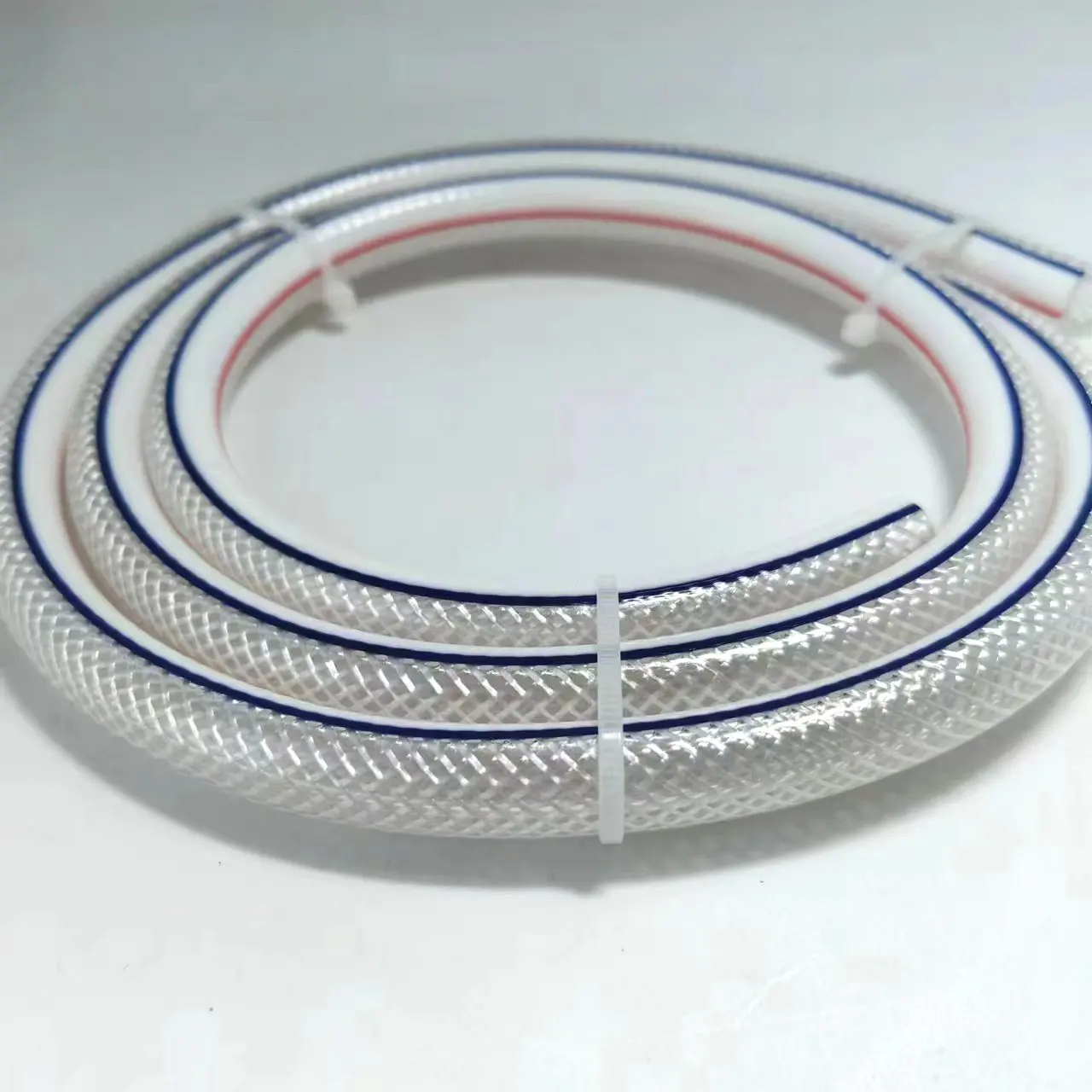

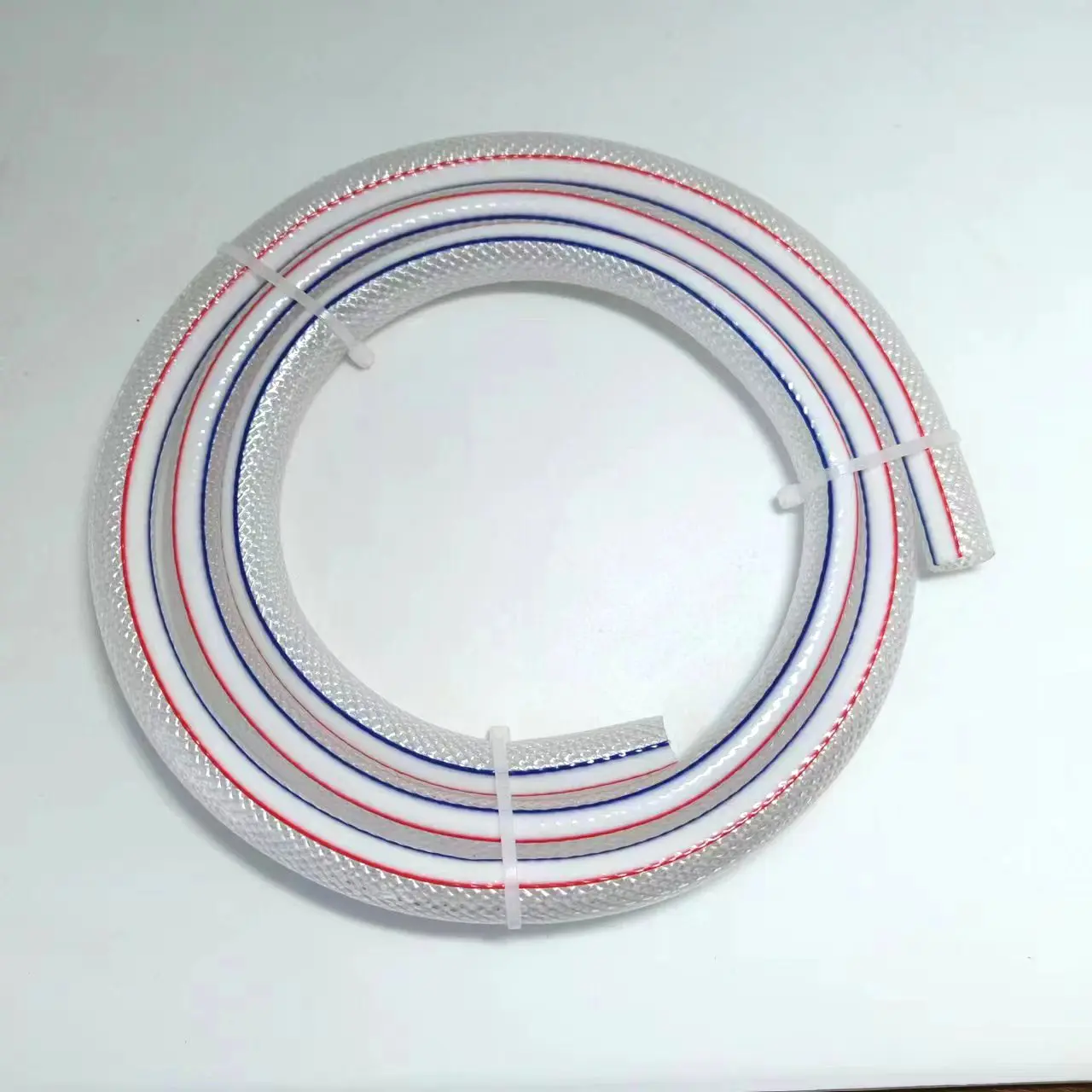

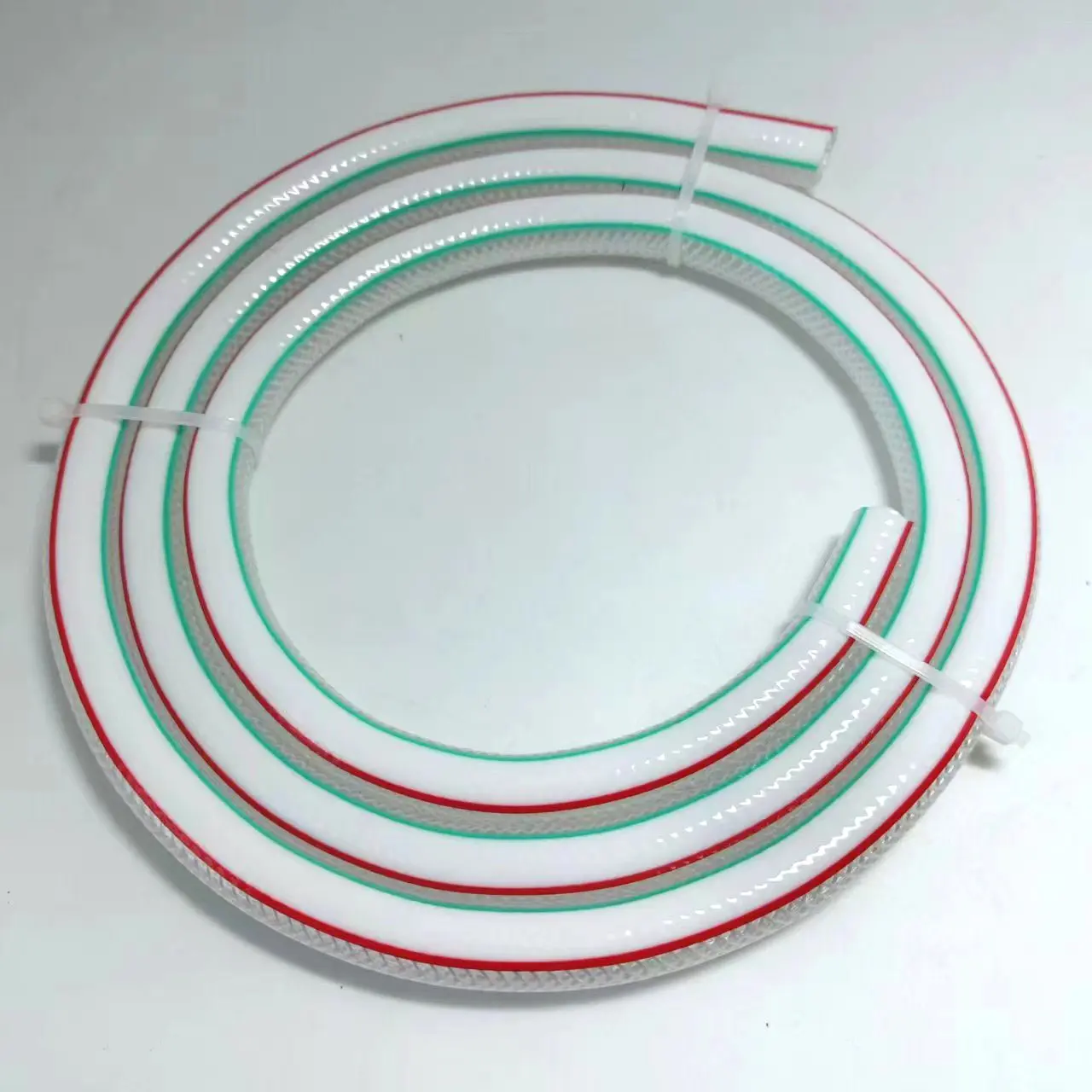

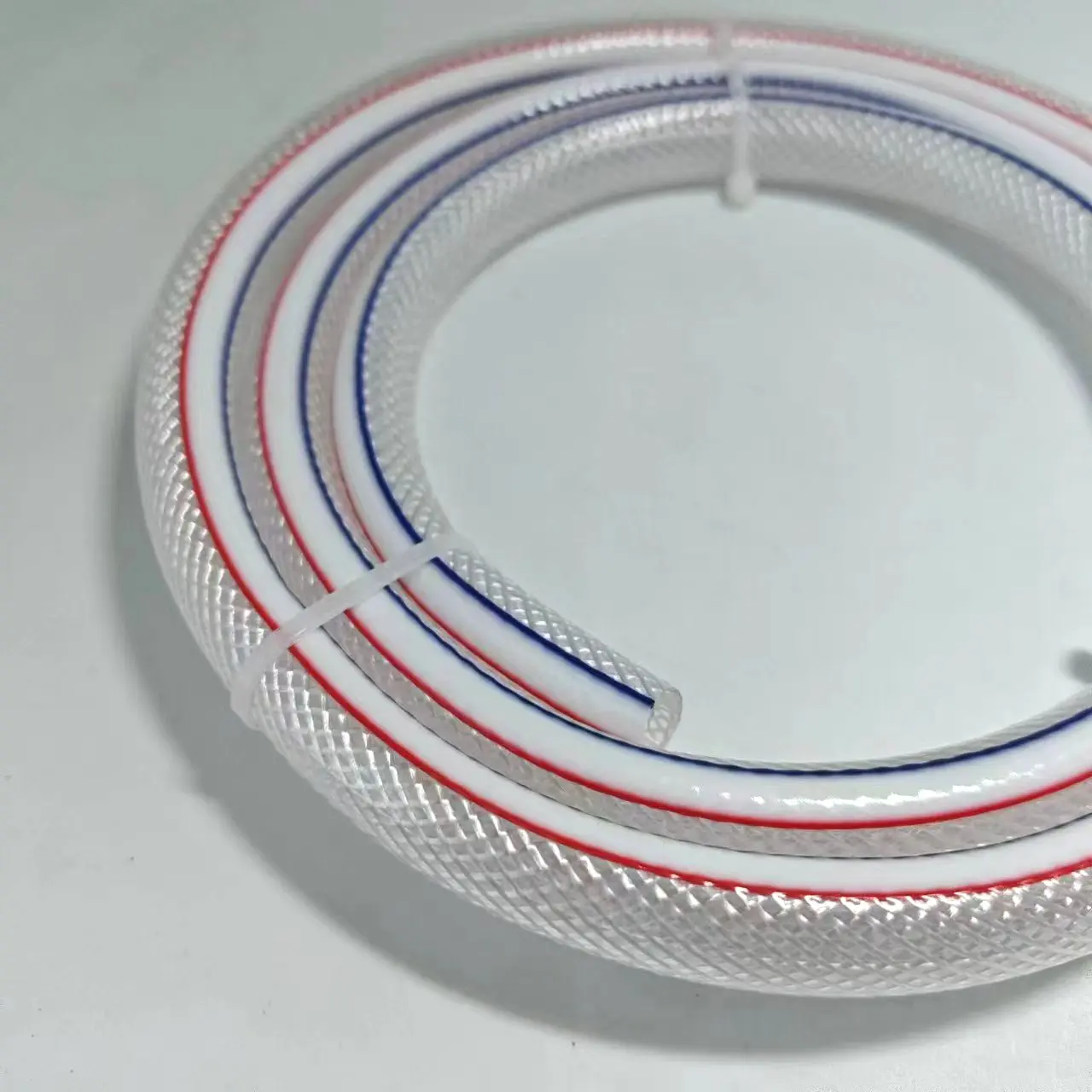

Introduction to PVC Fiber Reinforced Hose

PVC fiber reinforced hoses are widely used in various industries due to their flexibility, durability, and cost-effectiveness. These hoses consist of a PVC inner layer reinforced with high-strength polyester or other synthetic fibers, providing enhanced structural integrity without sacrificing pliability.

In the UK, these hoses are commonly employed in agriculture, construction, and industrial applications where lightweight yet robust tubing is required. Unlike rubber hoses, PVC fiber reinforced hoses are easier to handle and store, making them a preferred choice for many businesses. The UK market favors them for their resistance to abrasion and ability to maintain performance in different weather conditions, which is particularly relevant given the country's variable climate.

The manufacturing process involves extrusion of PVC with embedded fiber reinforcement, ensuring a balanced combination of strength and flexibility. While they are not designed for extreme chemical resistance, their primary advantage lies in general-purpose fluid transfer tasks. British industries appreciate their adaptability, as they can be used for water delivery, light drainage, and air ventilation without requiring specialized maintenance.

Applications in UK Industries

Irrigation Systems: Farmers use these hoses for water distribution in fields and greenhouses.

Dairy Farming: They assist in wash-down operations and liquid manure handling.

Crop Spraying: Lightweight and easy to maneuver, they are suitable for pesticide and fertilizer application.

Construction

Dewatering: Contractors utilize them for draining excess water from construction sites.

Dust Suppression: They help in spraying water to minimize airborne dust.

Concrete Pumping: Some variants are used for transferring liquid concrete in smaller projects.

Industrial & Municipal

Wastewater Management: Local councils use them for temporary drainage solutions.

Cleaning Operations: Factories and warehouses employ them for floor washing and equipment cleaning.

Ventilation: They assist in directing airflow in confined spaces.

The UK’s emphasis on efficient resource management makes these hoses a practical choice for businesses looking for reliable yet affordable solutions.

Advantages Over Alternative Materials

PVC fiber reinforced hoses offer several benefits compared to rubber, polyethylene, or metal hoses, particularly in the UK context:

Lightweight & Easy Handling: Unlike rubber hoses, they are easier to transport and deploy, reducing labor strain.

Cost-Effective: They are more affordable than rubber or metal alternatives, making them ideal for budget-conscious operations.

Weather Resistance: The UK’s damp climate can accelerate wear in some materials, but PVC hoses resist moisture-induced degradation.

Flexibility: They can be coiled and stored without losing shape, which is advantageous in space-limited environments.

Abrasion Resistance: Reinforced fibers prevent premature wear from rough surfaces, extending usability.

While they may not match the extreme durability of steel-reinforced hoses, their balance of performance and affordability makes them a staple in many British industries.

Specification

| Inner Diameter | Thickness | Length/Roll | Weight | Working Pressure (23℃) | Volume | ||

| inch | mm | mm | m | kg/m | bar | psi | cbm |

| 1/4 | 6 | 2 | 100 | 0.068 | 8 | 120 | 0.015 |

| 3 | 100 | 0.114 | 10 | 150 | 0.019 | ||

| 5/16 | 8 | 2 | 100 | 0.085 | 8 | 120 | 0.020 |

| 3 | 100 | 0.14 | 10 | 150 | 0.029 | ||

| 3/8 | 10 | 2 | 100 | 0.102 | 8 | 120 | 0.025 |

| 3 | 100 | 0.165 | 10 | 150 | 0.030 | ||

| 1/2 | 12 | 2 | 100 | 0.119 | 7 | 105 | 0.034 |

| 2.5 | 100 | 0.154 | 8 | 120 | 0.036 | ||

| 3 | 100 | 0.191 | 10 | 150 | 0.042 | ||

| 5/8 | 15 | 2 | 100 | 0.144 | 6 | 90 | 0.035 |

| 2.5 | 100 | 0.186 | 7 | 105 | 0.042 | ||

| 3 | 100 | 0.229 | 8 | 120 | 0.050 | ||

| 3/4 | 19 | 2 | 100 | 0.178 | 5 | 75 | 0.043 |

| 2.5 | 100 | 0.228 | 6 | 90 | 0.050 | ||

| 3 | 100 | 0.28 | 7 | 105 | 0.060 | ||

| 1 | 25 | 2 | 100 | 0.229 | 3 | 45 | 0.055 |

| 2.5 | 100 | 0.291 | 4 | 60 | 0.065 | ||

| 3 | 100 | 0.356 | 5 | 75 | 0.075 | ||

| 1 1/4 | 32 | 3 | 100 | 0.445 | 4 | 60 | 0.109 |

| 4 | 100 | 0.61 | 5 | 75 | 0.120 | ||

| 1 1/2 | 38 | 3 | 100 | 0.521 | 4 | 60 | 0.141 |

| 4 | 100 | 0.712 | 6 | 90 | 0.143 | ||

| 2 | 50 | 4 | 100 | 0.916 | 2 | 30 | 0.198 |

| 5 | 100 | 1.166 | 3 | 45 | 0.215 | ||

| 6 | 100 | 1.424 | 4 | 60 | 0.300 | ||

Environmental Considerations

The UK has stringent environmental regulations, and PVC fiber reinforced hoses align with sustainability efforts in several ways:

Recyclability: PVC is recyclable, and many UK waste management facilities accept these hoses for reprocessing.

Reduced Material Waste: Their long service life means fewer replacements, lowering overall waste generation.

Energy Efficiency in Production: Manufacturing PVC hoses consumes less energy compared to metal or rubber alternatives.

However, concerns over PVC disposal persist, prompting some businesses to explore biodegradable alternatives. Despite this, PVC fiber reinforced hoses remain widely used due to their practicality and established recycling pathways in the UK.

Maintenance and Storage Best Practices

Proper care ensures optimal performance of PVC fiber reinforced hoses in the UK’s often harsh weather conditions:

Avoid Prolonged Sun Exposure: UV rays can degrade PVC over time; storing hoses in shaded areas prolongs lifespan.

Clean After Use: Residual debris can cause blockages or accelerate wear.

Coil Properly: Kinks and twists weaken fibers; loose coiling prevents damage.

Winter Precautions: Freezing temperatures can make PVC brittle; draining hoses after use prevents cracking.

Following these practices helps businesses maximize the value of their hose investments.

Market Availability in the UK

PVC fiber reinforced hoses are readily available across the UK through industrial suppliers, hardware stores, and online distributors. Their affordability and versatility ensure steady demand, particularly in sectors like agriculture and construction. While specialty hoses exist for niche applications, standard reinforced PVC hoses remain a go-to solution for everyday fluid transfer needs.

The UK market continues to favor these hoses due to their balance of performance, cost, and ease of use, making them a staple in many operational environments.